Fiberglass pultrusion machines have become indispensable tools in modern manufacturing, offering unmatched efficiency and precision in the production of lightweight and durable composite materials. The process of pultrusion, a portmanteau of the words 'pull' and 'extrusion,' involves pulling raw fiberglass materials through a resin bath and subsequently through a heated die to form continuous lengths of reinforced polymer shapes. This technique is critical for industries seeking high-strength components, making it a topic of great importance for manufacturers and business owners aiming to optimize production processes.

The journey to mastering fiberglass pultrusion machines begins with understanding the versatile applications they cater to. From construction to automotive and even aerospace industries, these machines are renowned for producing profiles that boast excellent resistance to corrosion and environmental factors. Products like ladders, handrails, and cable trays are just a few examples of everyday items crafted using pultrusion techniques. The demand for such products is on the rise, highlighting the growing importance of fiberglass pultrusion machines in the manufacturing world.

Investing in a high-quality fiberglass pultrusion machine can significantly impact a company's operational efficiency and product quality. The expertise involved in selecting the right machine is crucial; factors such as the type of resin system, fiber reinforcement, and the desired cross-sectional profile all play roles in the decision-making process. A seasoned expert in composites manufacturing would emphasize the importance of customizing the pultrusion set-up to align with specific production goals, ensuring that the machinery is not only fit for purpose but also optimized for maximum output and minimal maintenance.

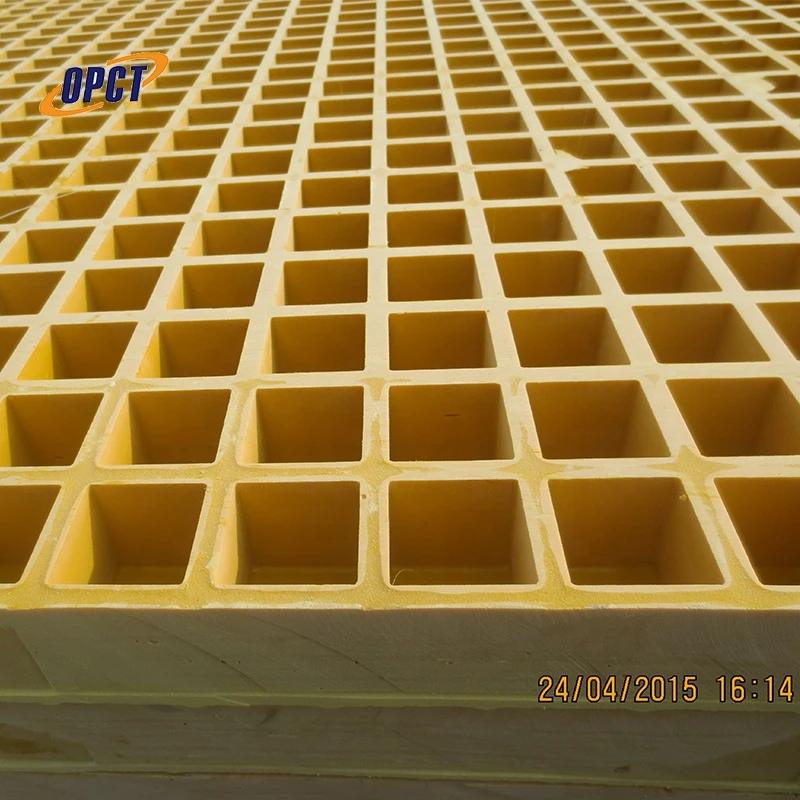

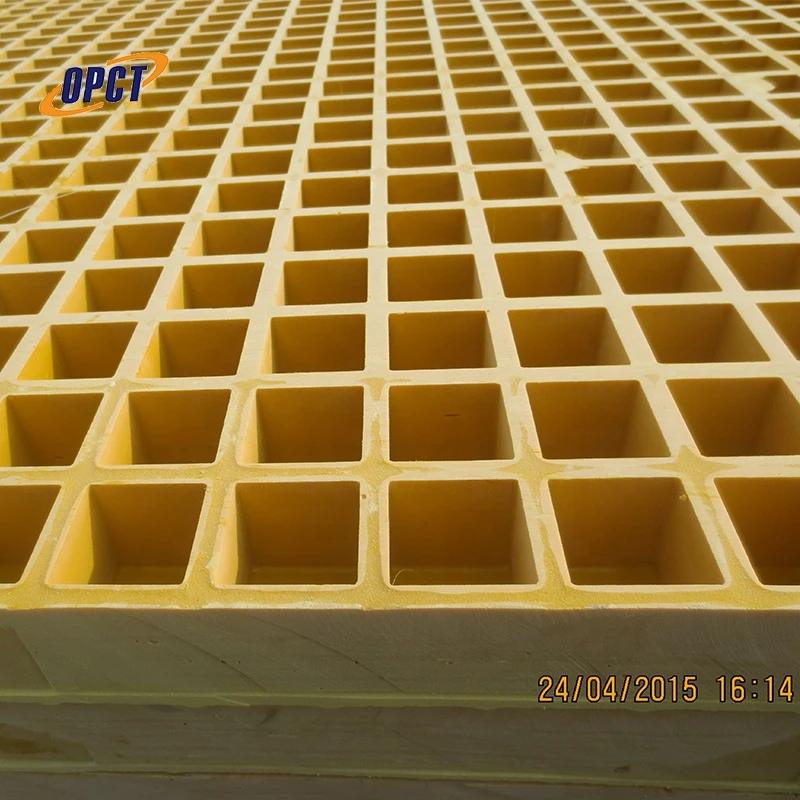

One of the primary advantages of using fiberglass pultrusion machines lies in their ability to produce extremely consistent products with tight tolerances. The precision involved in the pultrusion process allows for the production of components with uniform dimensions and superior surface finish. This reliability makes pultruded products particularly appealing in industries where specification adherence is non-negotiable. An experienced operator knows that maintaining strict control over the production environment, including the temperature and speed settings, is fundamental to achieving such consistency.

fiberglass pultrusion machine

Trustworthiness in fiberglass pultrusion also stems from the machine's ability to handle a variety of complex shapes and sizes. Manufacturers often require bespoke solutions, and a reliable pultrusion setup can accommodate these needs. This adaptability is particularly beneficial for projects that require customization without compromising on the structural integrity of the final product. Working with a reputable supplier ensures that the machinery adheres to international standards, further bolstering the trust placed in these machines by companies worldwide.

The professional expertise required to operate a fiberglass pultrusion machine cannot be overstated. Skilled technicians are essential to monitor the process, adjust parameters, and perform maintenance tasks to ensure uninterrupted functionality. Training and development in this niche area are crucial; seasoned operators bring a level of ingenuity and problem-solving that directly translates to productivity and quality assurance. Furthermore, their deep understanding of the machine's mechanics facilitates smoother adaptations to new materials and design requirements.

Finally, the authoritativeness of a fiberglass pultrusion machine manufacturer plays a critical role in influencing purchasing decisions. Companies that have a proven track record of innovation in composite technology and a comprehensive after-sales support system inspire confidence in potential buyers. This assurance of continued assistance and product evolution forms the backbone of a thriving partnership between machine suppliers and manufacturing companies.

In conclusion, fiberglass pultrusion machines represent a pivotal investment for businesses aiming to carve a niche in the competitive world of composites manufacturing. With their precise engineering, adaptability, and reliance on skilled operation, these machines empower industries to innovate and expand their product offerings. The synthesis of technical expertise and robust machinery invariably leads to enhanced production capacities and product excellence. Through continued advancement and commitment to quality, fiberglass pultrusion machines will remain at the forefront of manufacturing innovation, driving growth and success for companies worldwide.