In the expanding world of industrial and residential infrastructure, the demand for efficient water storage solutions is unceasing.

The 200 cubic meter (200m3) water tank stands out as a pivotal choice for both large-scale industrial applications and significant residential needs. Understanding the intricate aspects of this sizable water tank not only underscores its importance but also serves to amplify its relevance across various sectors.

When examining the expertise required in manufacturing these tanks, it's imperative to consider the materials used. Typically constructed from robust materials such as concrete, steel, or fiberglass-reinforced plastic, these tanks are designed to withstand both time and environmental elements. The material choice directly impacts factors like durability, maintenance, and overall cost, which are intricate details essential for a product of this calibre.

Moving from manufacture to application, these tanks are a testament to engineering prowess. For instance, their installation is no small feat. It involves comprehensive groundwork, including site preparation, ensuring environmental compliance, and often logistical challenges, especially in remote or compact urban locations. The expertise required for such installations underscores the need for skilled labor and meticulous planning, emphasizing the professional depth involved in deploying such a solution.

From an authoritative standpoint, the engineering principals embedded in the design and functionality of the 200m3 water tank play a crucial role. Adhering to internationally recognized standards such as ISO or API (American Petroleum Institute) not only reassures end-users of quality and reliability but also reflects the technological advancements in the field. Tank design is optimized to maximize storage while ensuring stability, and safety features are incorporated to guard against potential overflows or leaks, further establishing the authority these tanks command in the market.

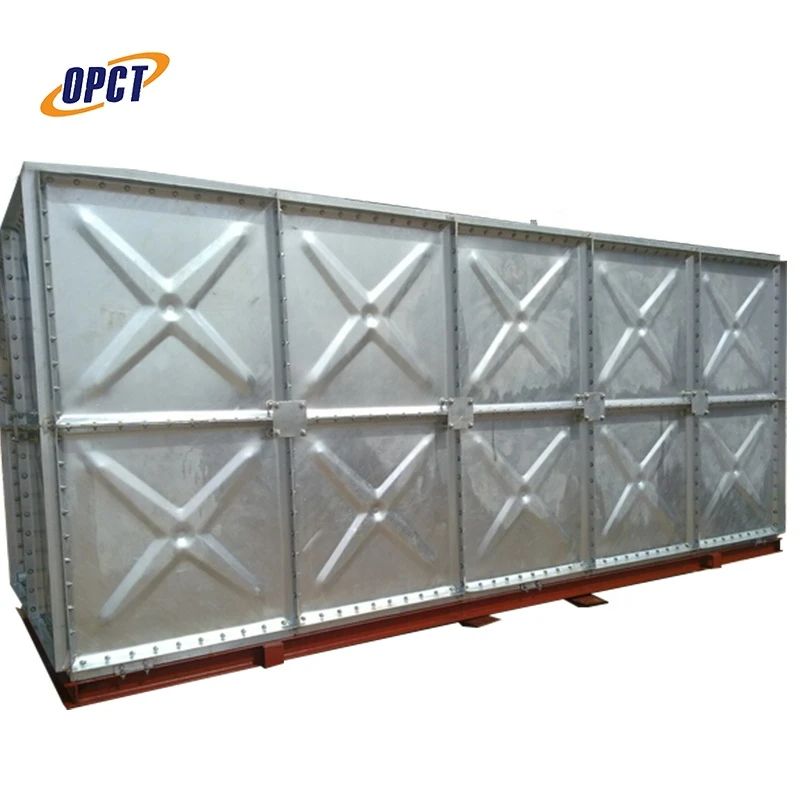

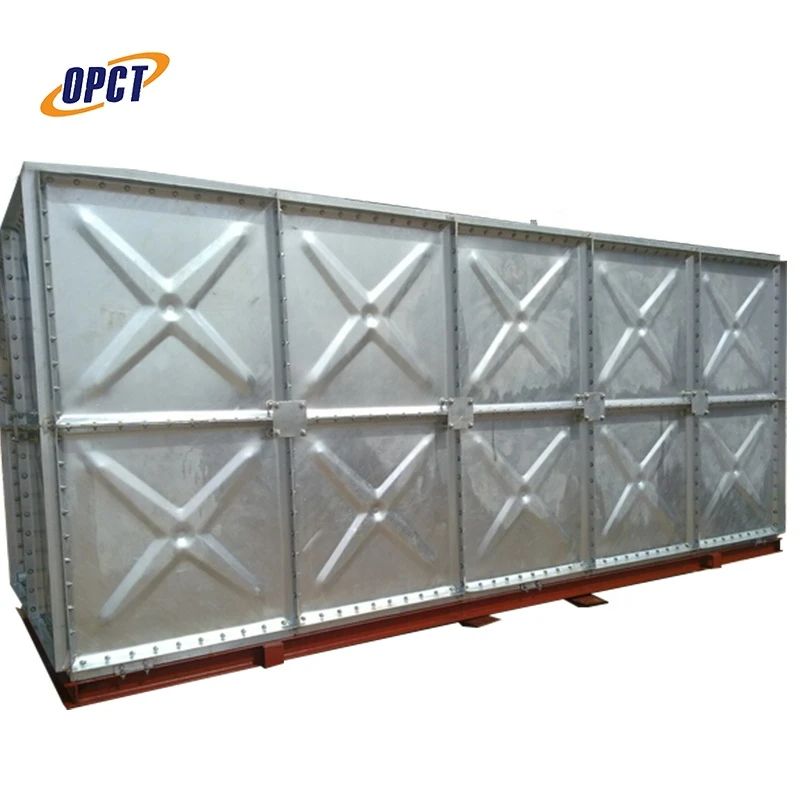

200m3 water tank

In terms of trustworthiness, the real-world application and testimonials from industries often speak volumes. Sectors such as agriculture, manufacturing, and municipal water management heavily rely on these tanks for day-to-day operations. For instance, in irrigation, a 200m3 water tank can ensure consistent water supply during dry spells, drastically impacting crop yield and, consequently, profitability. In urban planning, these tanks often serve as critical reserves for emergency situations, including firefighting or unexpected supply disruptions, making them indispensable.

Moreover, long-term cost-efficiency is another layer that adds to the dependability and attraction of these storage solutions. While the initial investment may seem substantial, the longevity and minimal maintenance compared to smaller, less efficient models, along with the benefit of economies of scale, often result in significant savings over time.

For stakeholders considering the integration of a 200m3 water tank into their operations, the decision pivotally rests on understanding its multifaceted benefits. Expert consultations and case studies play an invaluable role here, providing insights into operational efficiencies and potential pitfalls based on similar implementations.

To summarize, the 200m3 water tank epitomizes more than just large-scale water storage; it embodies a blend of engineering excellence, reliability, and strategic forethought. As industries continue to evolve, the essential role of these tanks in supporting sustainable and efficient water management solutions becomes increasingly undeniable. Whether it is about addressing immediate storage needs or planning for future challenges, this product is more than equipped to deliver, enhancing productivity and ensuring peace of mind for those who wisely invest in it.