Navigating the Domain of Chemical Storage Solutions A Comprehensive Exploration of Chemical Tanks for Sale

In the dynamic world of industrial applications, the need for specialized storage solutions for chemicals is critical. Chemical tanks, sold under various configurations and designs, epitomize the blend of scientific precision, engineering excellence, and regulatory compliance. This exploration delves into the nuances of chemical tanks available for sale, encapsulating their significance, specifications, and strategic benefits for industries across the globe.

Chemical tanks are the unsung heroes in sectors such as manufacturing, pharmaceuticals, agriculture, and waste management. They stand as bastions of safety, ensuring hazardous materials are securely contained, thus averting potential disasters. This article aims to illuminate the intricacies of acquiring these storage solutions, underscoring the parameters that dictate their selection and utilization.

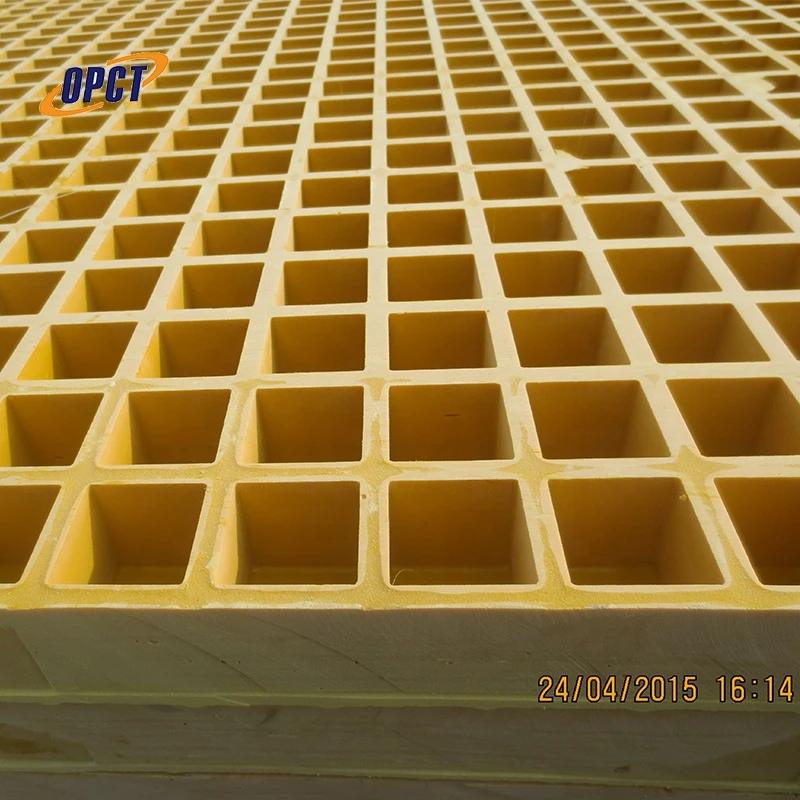

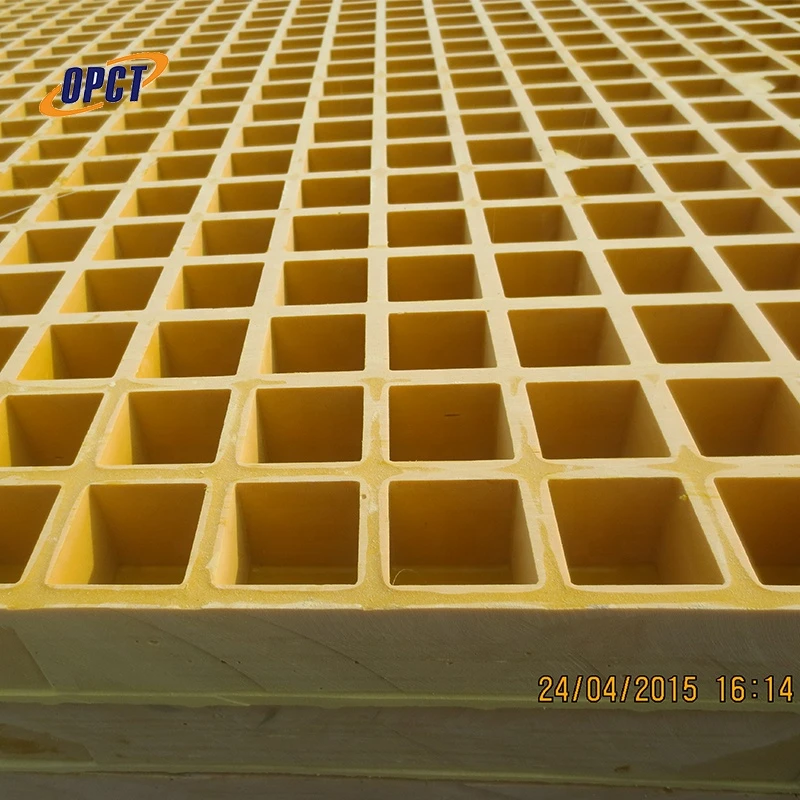

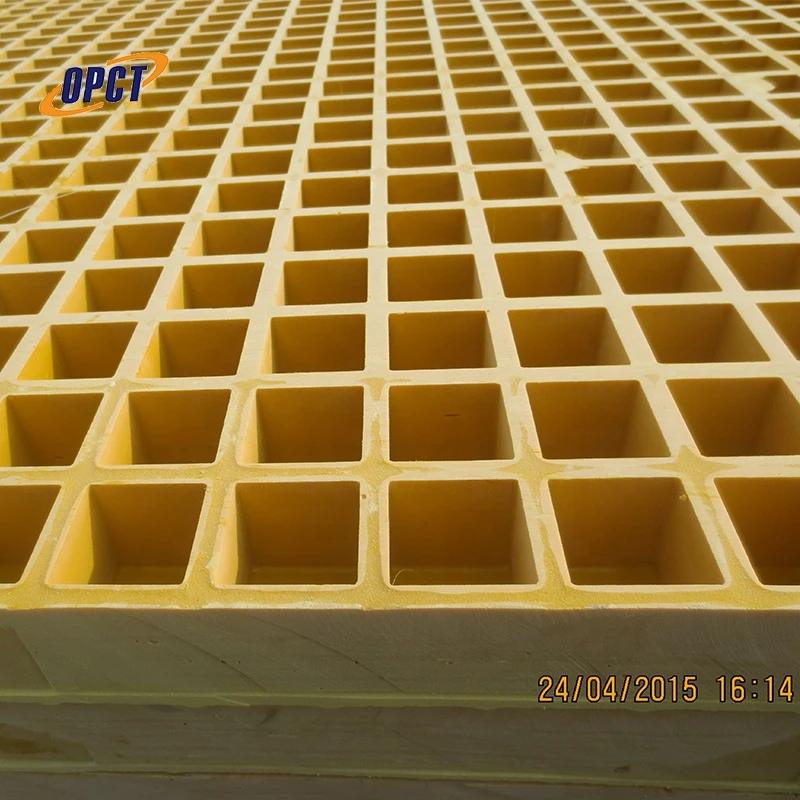

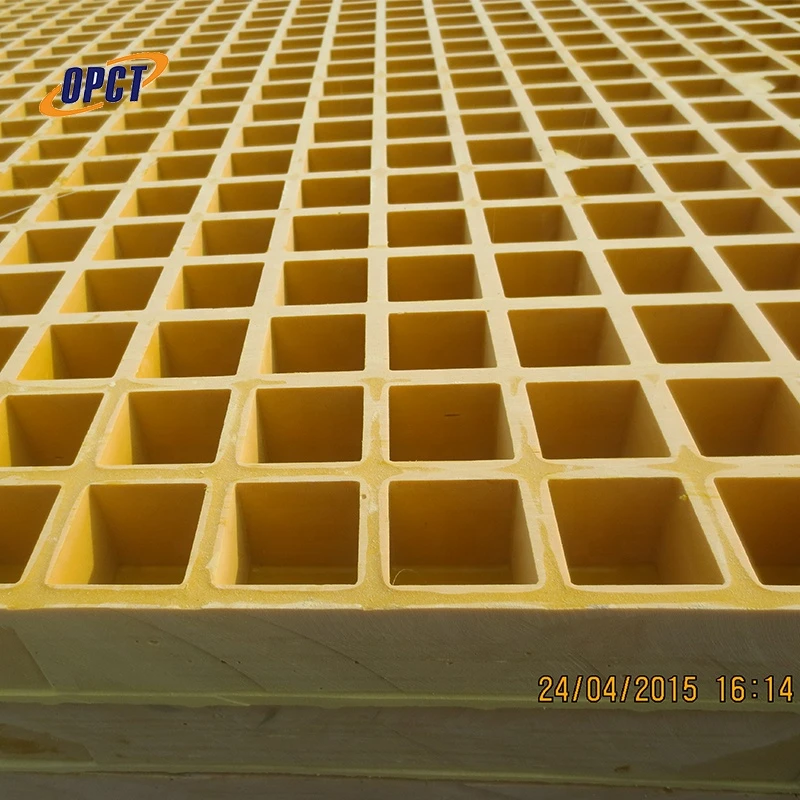

A key aspect of chemical tank purchases is understanding material compatibility. Chemical tanks span a spectrum of materials — stainless steel, polyethylene, fiberglass-reinforced plastic (FRP), and more — each offering unique advantages. Stainless steel tanks are renowned for their durability and resistance to corrosion, making them ideal for storing acids and caustic substances. Polyethylene tanks, alternatively, are versatile and cost-effective, widely used for their chemical inertness and lightweight properties.

The expertise in selecting chemical tanks also involves discerning the right capacity for your specific needs. Tanks are engineered in various capacities, from small, transportable units to massive, stationary tanks, accommodating thousands of gallons. This flexibility is pivotal for businesses to scale operations efficiently, safeguarding their inventories effectively without overspending on superfluous storage space.

chemical tanks for sale

Further, the intricacies of tank design incorporate safety features tailored to chemical-specific requirements. Innovations include double-walled construction for spill prevention, UV inhibitors for outdoor tanks, and fittings that facilitate easy transfer and mixing operations. Such features reflect the industry's commitment to safety and efficiency, mitigating the risks associated with chemical handling and storage.

Equally important is adherence to environmental and regulatory standards. Reputable manufacturers and vendors prioritize compliance with local and international guidelines such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA). These regulations mandate specifications that ensure the health and safety of workers and the environment. Purchasing a chemical tank from a certified supplier not only mitigates compliance risks but also reinforces the credibility of an organization's operational procedures.

The authority that seasoned suppliers bring to the table cannot be overstated. Their insights into chemical compatibility, industry trends, and regulatory changes equip businesses with the knowledge to make informed decisions. Furthermore, established relationships with manufacturers allow for customization of tanks, ensuring that specific industry needs are met with precision engineering.

Trustworthiness emerges as a decisive factor in engaging with suppliers of chemical tanks. Verified testimonials, comprehensive service agreements, and post-purchase support options are indicators of a reliable vendor. Due diligence in assessing these parameters can avert costly mistakes and operational hiccups in the future.

In conclusion, the sale of chemical tanks encompasses much more than the mere transaction of goods; it is an investment into an infrastructure that prioritizes safety, efficiency, and compliance. As businesses navigate this essential facet of industrial operations, a firm grasp of the nuances involved will position them to optimize their storage solutions effectively. This exploration asserts the value of professional advice, quality assurance, and a proactive approach to regulatory adherence — pillars that underpin successful chemical storage management. Embracing these elements ensures that enterprises not only meet their immediate needs but also fortify their capabilities for future expansions and technological advancements.