For industries that rely on chemical storage solutions, the 200 gallon chemical tank stands out as an essential asset due to its versatility and reliability. Constructed from high-grade polyethylene or similar durable materials, these tanks provide a safe and efficient method to store and handle a diverse range of chemicals — from corrosive acids to benign solvents. The relatively compact yet capacious design makes it a preferred choice for businesses with moderate storage needs, ensuring that operations can continue smoothly without frequent refills or interruptions.

In terms of selecting the best 200 gallon chemical tank, understanding the specific requirements of your chemical handling process is crucial. Each tank is engineered to withstand the unique challenges posed by different chemical compounds. This specialization ensures that tank materials resist degradation over time, thereby extending the lifespan of the product and reducing long-term costs. Companies relying unnecessarily on generic tanks might find themselves facing maintenance issues, leakage potential, or even regulatory fines due to non-compliance with safety standards.

A hallmark of a quality 200 gallon tank is its compliance with regulatory standards, such as those set by the Occupational Safety and Health Administration (OSHA) or the Environmental Protection Agency (EPA) in the United States. These standards guide businesses to choose tanks with appropriate secondary containment measures, leak detection systems, and certifications that attest to their readiness for storing specific chemicals. A tank that meets these standards not only protects the environment but significantly enhances workplace safety, which is an essential component of trustworthiness and reliability.

An equally important factor in the decision-making process is the tank’s adaptability to the current technological advancements in chemical storage. Modern tanks often come equipped with features such as built-in heating systems, internal coating for enhanced chemical resistance, or automated control interfaces for monitoring tank levels and conditions remotely.

Integration with industry 4.0 technologies, such as Internet of Things (IoT) systems, allows for real-time data acquisition and facilitates predictive maintenance, ensuring that downtime is minimized and productivity is maximized.

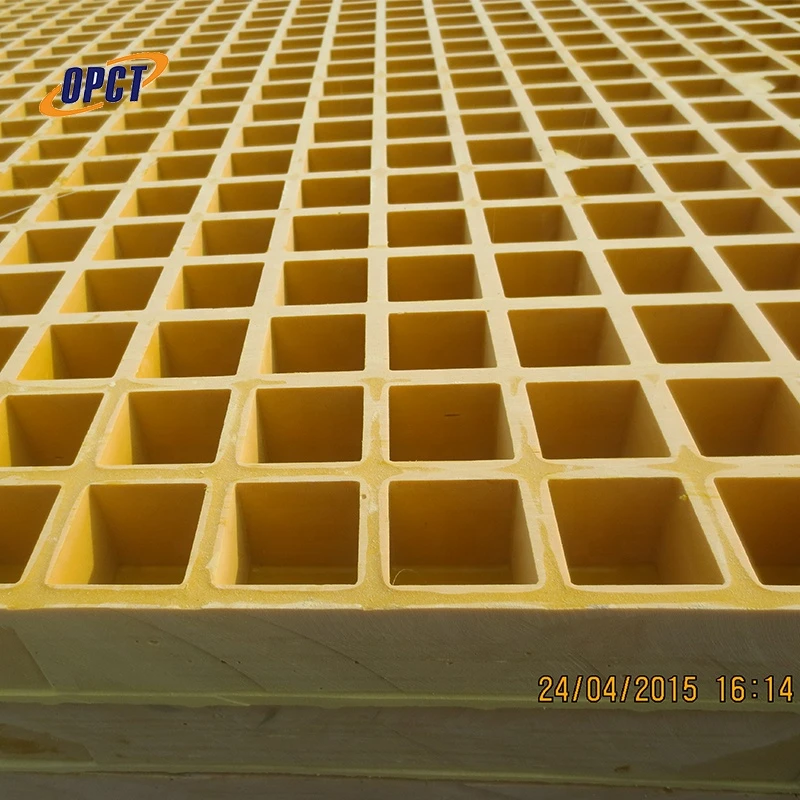

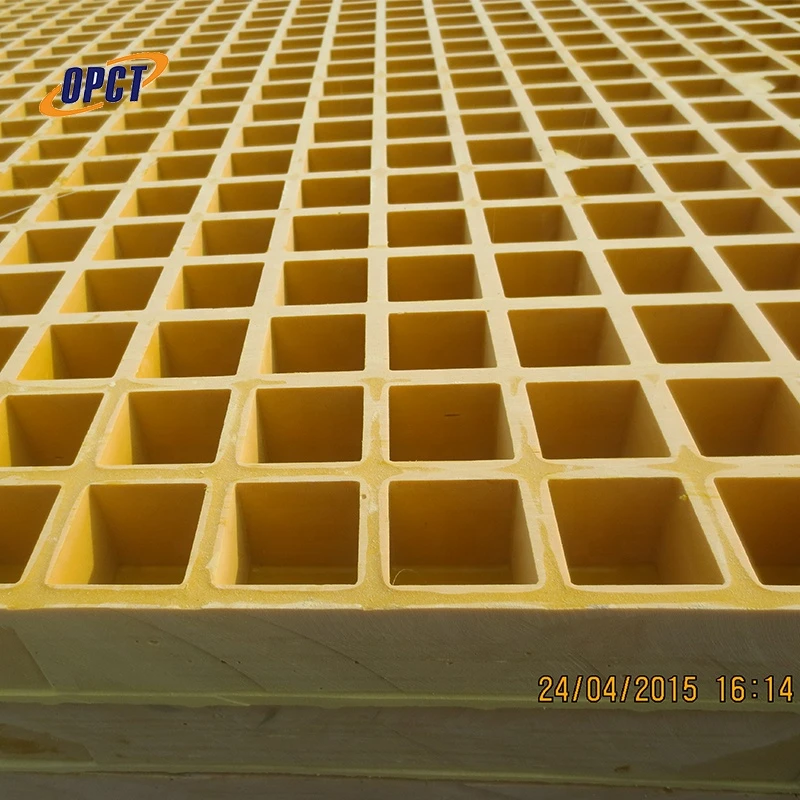

When installed with proper accessories, these tanks can be fitted to cater to a wide array of industry applications. They can interlink with a network of pipes for scalable distribution, connect to mix-and-match fittings for ease of integration with other equipment, or adapt to mobile skid systems for flexible deployment. This versatility underscores the expertise involved in crafting these tanks to suit various industry needs, from pharmaceuticals to agriculture, and manufacturing to waste management.

200 gallon chemical tank

To ensure the investment into a 200 gallon chemical tank is savvy, consult with industry experts who provide tailored advice based on in-depth analyses of chemical properties, storage aims, and operational logistics. These discussions should extend beyond mere product specifications to consider on-site environmental factors, such as spatial constraints, climate influence, and emergency system requirements. By aligning with someone possessing considerable expertise, businesses can make informed decisions that further enhance both operational efficiency and safety.

Moreover, an aspect that often gets overlooked is the role of expert installation and regular maintenance carried out by certified professionals. Tanks that are poorly installed or inadequately maintained risk compromising safety and efficiency. Regular inspections, integrity testing, and cleanliness ensure the tanks remain in prime condition and highlight the effectiveness of having a robust maintenance schedule. Such diligence embodies the product's authoritativeness, reinforcing its capacity to safeguard both the storage substances and the individuals working in proximity.

A noteworthy point regarding the trustworthiness of suppliers is their commitment to delivering customer service that includes comprehensive warranty plans, detailed user manuals, and prompt technical assistance. These services demonstrate a dedication to maintaining customer satisfaction and long-term product performance, further solidifying the tank’s credibility in the industry. Partnering with manufacturers renowned for their reputation in crafting enduring, top-quality chemical tanks can provide significant peace of mind and reliability in regular operations.

In conclusion, a strategic investment in a 200 gallon chemical tank goes beyond the purchase itself; it involves an informed approach towards selecting the appropriate model, complying with regulatory norms, integrating advanced features, ensuring proper installation and maintenance, and collaborating with reputable suppliers. These factors collectively contribute to a seamless storage solution that enhances operational efficiency, safety, and sustainability — key components that sympathetically align with the principles of Experience, Expertise, Authoritativeness, and Trustworthiness in the context of chemical storage management.