Stainless steel water tank fabrication represents the epitome of durability and efficiency, serving as a cornerstone in a range of applications, from household water storage solutions to industrial liquid management systems. This seamless blend of innovation and tradition sets the standard for water storage, offering unmatched longevity and reliability. Understanding the intricacies of stainless steel water tank fabrication, however, reveals why it is such a preferred choice across various sectors.

Stainless steel, an alloy renowned for its corrosion resistance, sturdiness, and hygienic properties, forms the backbone of high-quality water tank fabrication. The manufacturing process begins with selecting premium-grade stainless steel, commonly 304 or 316, each known for their excellent corrosion-resistant properties. The choice between these grades is pivotal; type 304 stainless steel is extensively used for its affordability and adequate resistance in most environments, while type 316 is often employed where extreme corrosion-resistance is required, such as in coastal areas or industries involving specific chemical processes.

The fabrication process itself is an example of engineering excellence, demanding specialized expertise and experienced technicians. Engineers meticulously design water tanks to meet specific requirements, ensuring optimal thickness and support structures to withstand external pressures and environmental fluctuations. This phase involves cutting-edge CAD software for precision in design and layout, reflecting the integration of technology in modern manufacturing processes.

Welding, a critical phase in fabrication, further exemplifies the need for expertise. This step requires skilled artisans who utilize advanced welding techniques such as TIG (Tungsten Inert Gas) welding, which guarantees strong, non-corrosive joints essential for maintaining the tank's integrity over many years. Post-welding, tanks undergo rigorous quality checks, including hydrostatic testing to verify strength and ensure there are no leaks, reinforcing their trustworthiness for safe water storage.

Surface finishing, crucial for enhancing the tank's longevity and aesthetic appeal, involves meticulous processes like grinding, buffing, and electropolishing. These processes not only offer a visually appealing finish but also maximize the hygienic properties of stainless steel by creating a smooth, non-porous surface that hinders bacterial growth and facilitates easy cleaning, making these tanks a staple in industries where sanitation is paramount.

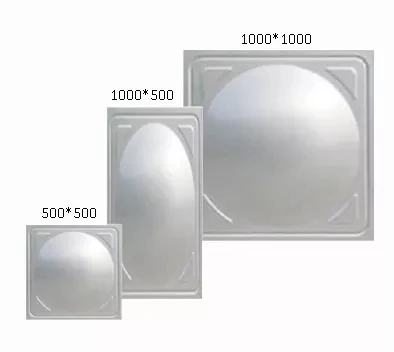

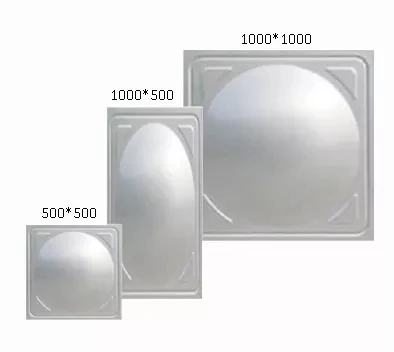

stainless steel water tank fabrication

The environmental advantages of stainless steel water tanks also underpin their widespread adoption. They are inherently eco-friendly; stainless steel is 100% recyclable, playing a significant role in reducing environmental impact. The long lifecycle of these tanks means fewer replacements, which translates to less material waste over time, positioning stainless steel tanks as a sustainable choice for the environmentally conscious consumer or business.

In industrial settings, stainless steel water tanks serve diverse roles, from storing potable water to holding chemicals in manufacturing processes. Their resistance to contamination and ability to withstand high pressures make them indispensable in sectors like pharmaceuticals, food processing, and chemical manufacturing, where both safety and sterility can never be compromised.

For homeowners, these tanks offer peace of mind with minimal maintenance requirements. Their resistance to rust and structural damage ensures that the water remains clean and safe for consumption, a crucial aspect for households reliant on rainwater harvesting systems or in areas with limited municipal water supply.

In essence, stainless steel water tank fabrication is not merely a manufacturing process but a sophisticated craft that combines technological advancements with proven materials science. This intersection of durability, sustainability, and design precision ensures that stainless steel water tanks remain a benchmark for water storage solutions globally. With constant innovations and technological strides, the future of stainless steel tank fabrication continues to promise enhanced efficiency, reinforced reliability, and increased accessibility, solidifying its standing as a leader in water storage technology.