In the expansive realm of industrial and commercial storage solutions, the stainless steel storage tank stands as a paragon of engineering excellence, underscored by decades of proven reliability, performance, and sustainable design. These tanks serve pivotal roles across various sectors, including food processing, pharmaceuticals, chemical manufacturing, and wine and beverage production, showcasing their versatility and critical importance.

The unwavering allegiance to stainless steel for tank fabrication is not without reason. Its composition chiefly involves the amalgamation of chromium, nickel, and carbon which imparts remarkable resilience against corrosion—a common adversary in storage solutions. This innate resistance ensures that the integrity of stored materials remains uncompromised, safeguarding against potential contamination. Such a feature is paramount in industries like pharmaceuticals and food processing, where the highest standards of hygiene are non-negotiable.

From an engineering perspective, stainless steel's robustness also offers a significant advantage in terms of structural integrity. These tanks are capable of withstanding substantial internal pressures and extreme temperature variations, making them suitable for storing high-pressure chemicals and thermal-sensitive materials. Furthermore, the material's formidable tensile strength curtails the risk of structural failure, providing assurance of long-term operational durability. This durability not only extends the lifespan of the tanks but also translates to cost-efficiency, minimizing the frequency and expenditure on repairs or replacements.

Customization emerges as another highlight of stainless steel storage tanks. Each industrial application presents unique challenges and specific requirements, necessitating bespoke solutions. Manufacturers can adeptly customize these tanks in varied shapes and sizes, integrating additional features like heating jackets, agitation systems, or insulation, to accommodate the peculiar storage needs of complex industrial processes. This level of customization is not easily achievable with alternative materials, affirming stainless steel's supremacy in the storage tank industry.

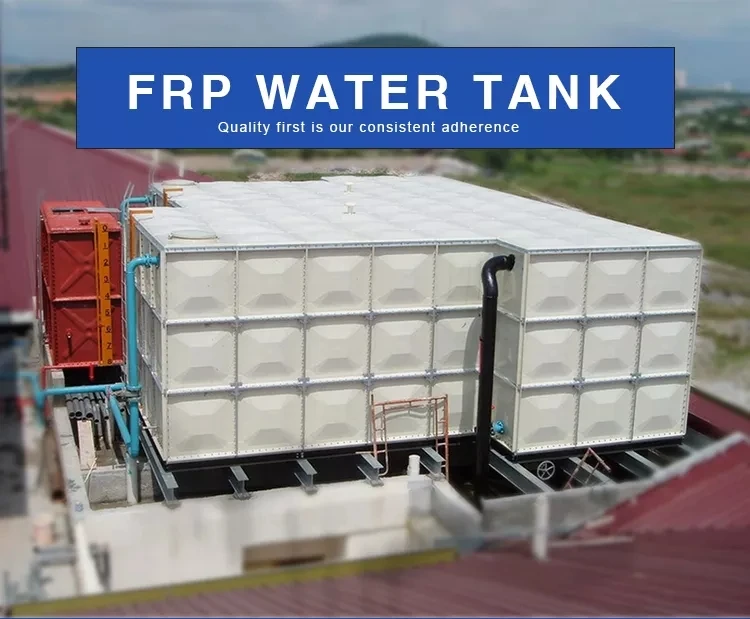

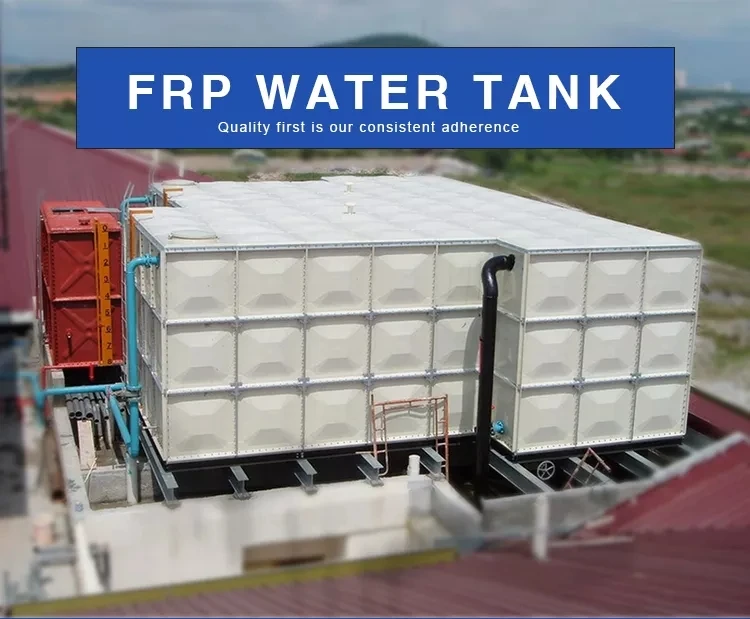

stainless steel storage tank

The environmental sustainability of stainless steel embodies yet another compelling advantage. As global paradigms shift towards eco-friendly industrial practices, stainless steel stands out due to its recyclability. At the end of its service life, a stainless steel tank can be repurposed, thus diminishing the carbon footprint associated with conventional industrial waste. This eco-conscious aspect aligns perfectly with the growing corporate responsibility mandates, enhancing the overall appeal of stainless steel tanks in modern industrial undertakings.

When considering the maintenance of stainless steel storage tanks, the demands are appreciably minimal. The non-porous surface discourages the harboring of bacteria and facilitates easy cleaning—an essential attribute in sectors demanding stringent sanitary conditions. Routine inspections predominantly involve simple, non-invasive checks, ensuring that the tanks continually meet operational standards without extensive downtime.

The decision to integrate stainless steel storage tanks into an operational framework is not solely grounded on their mechanical benefits but also supported by their endorsement from industry experts and regulatory bodies. Authorities in the manufacturing and health sectors often advocate for stainless steel due to its unparalleled properties and alignment with safety regulations.

In conclusion, the utilization of stainless steel storage tanks epitomizes a confluence of engineering innovation, economic prudence, and environmental stewardship. Their multifarious advantages across industries affirm their role as indispensable components in efficient material storage and processing. Embracing stainless steel storage tanks is not merely an investment in infrastructure but a strategic alignment with excellence and sustainability in industrial practices. As industries evolve and regulatory landscapes shift, the adaptability and prowess of stainless steel storage solutions continue to shine, asserting their place as the storage medium of choice for forward-thinking enterprises.