Sealing a galvanized water tank is an essential task that ensures longevity, functionality, and safety. As an experienced professional in the field, having worked extensively with water storage solutions, I've observed that successfully sealing a galvanized tank can be achieved through a meticulous process and an understanding of the materials involved.

Many homeowners and businesses choose galvanized steel tanks due to their durability and resistance to rust. However, despite their robust nature, these tanks are not impervious to leaks and corrosion, especially at the seams and joints, which necessitates proper sealing to avoid long-term deterioration and water contamination.

The first step in sealing a galvanized water tank involves a thorough inspection. Even the most negligible signs of wear - tiny rust spots, discolorations, or superficial scratches - need close attention. It's crucial to ensure the tank is completely empty before the inspection. This not only allows for a clearer view of the interior but also ensures safety and precision during the sealing process.

Once the inspection is complete, prepare the surface by cleaning the tank thoroughly. Use a non-corrosive cleaning agent to eliminate any grease, dirt, or remnants of old sealant material. A clean working surface is vital because contaminants can inhibit the adhesion of the sealant, leading to potential leaks.

Selecting the right sealant is a critical part of the sealing process. Through my experience, I recommend a silicone-based or polymer-based sealant designed specifically for metal surfaces. These sealants are flexible, durable, and resistant to temperature fluctuations, which is essential for an outdoor or semi-outdoor water storage solution. It’s important to consult product specifications and reviews to ensure that the chosen sealant is appropriate for use with potable water, thus guaranteeing the safety and quality of the water supply.

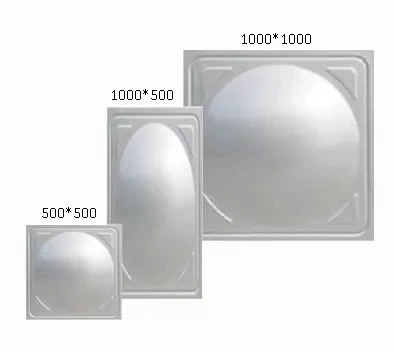

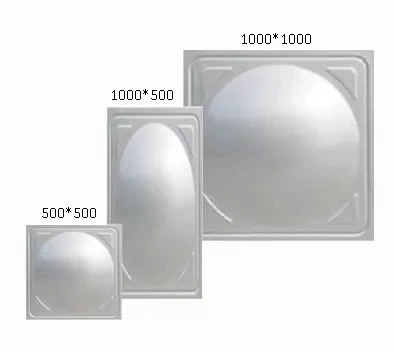

sealing a galvanized water tank

Application of the sealant requires steady hands and consistency. Use a high-quality caulking gun for accuracy and control. Begin at one end of a seam or joint and apply a continuous, even bead while moving the gun steadily to the other end. For internal coatings, make sure the product is properly dispersed on every surface to cover all potential points of leakage. A thin layer is often insufficient; thus, it might be necessary to apply multiple coats, allowing each layer to dry completely before proceeding with the next.

Patience during the drying phase is critical. Depending on the sealant used and environmental conditions such as humidity and temperature, the drying period can vary significantly. Manufacturers' guidelines provide optimal drying times; exceeding these recommendations is always safer than falling short to ensure complete efficacy and seal integrity.

Beyond the sealing process, establishing a routine examination schedule can save costs and extend the lifespan of the tank. Inspections and minor touch-ups at determined intervals allow for minor issues to be addressed before they develop into significant problems. This enduring vigilance fosters not only the tank's longevity but also continues assurance of water quality and safety.

For any significant repairs or incidents of repeated leakage, consulting with a specialist in galvanized tank maintenance is advised. Professionals bring a wealth of expertise, coupled with access to industry-standard tools and materials, often identifying underlying issues that may go unnoticed by the untrained eye.

In conclusion, sealing a galvanized water tank, if done correctly, serves not only an immediate function but also provides long-term benefits, reinforcing the tank's integrity and performance. By choosing quality materials, applying them meticulously, and maintaining a regular inspection routine, one can significantly prolong the service life of these critical structures. Whether for residential, agricultural, or industrial use, the proper sealing of galvanized water tanks is a cornerstone of effective water management and sustainability.