Pure iron nails have transcended their traditional role as basic joinery tools, evolving into essential components in various industries, from construction to manufacturing. As the global demand for high-quality, durable fastening solutions expands, factories dedicated to the production of pure iron nails are pivotal in supplying this critical need. These factories adhere to stringent quality standards to ensure that their products meet international specifications, catering to diverse applications and industries.

Experience garnered over decades has positioned these factories as leaders in the pure iron nail manufacturing sector. By leveraging cutting-edge technology and modern engineering techniques, these facilities are able to produce nails that not only meet but often exceed the expectations of demanding industrial applications. The manufacturing process begins with the selection of top-grade iron raw materials, ensuring that the foundational element of the nails retains intrinsic strength and purity. This careful selection is crucial as it directly influences the longevity and efficacy of the final product.

The expertise that these factories bring to the table is underpinned by continuous research and development endeavors. Many of these plants invest heavily in R&D to innovate and refine their production processes. This commitment results in the development of nails that are resistant to corrosion, which is especially important in construction environments exposed to moisture and fluctuating weather conditions. Advanced galvanization techniques and heat treatment processes further enhance the durability and strength of the nails, providing additional assurance of performance and reliability.

Factories producing pure iron nails also maintain a focus on automation to ensure high production efficiency. State-of-the-art machinery and equipment facilitate precision manufacturing, ensuring consistency in nail size, weight, and strength. Automation not only enhances production rates but also minimizes the margin of error, reducing waste and ensuring that the products meet regulatory standards. This focus on technology and precision manufacturing is reflective of these factories' authoritative grasp of metallurgical best practices.

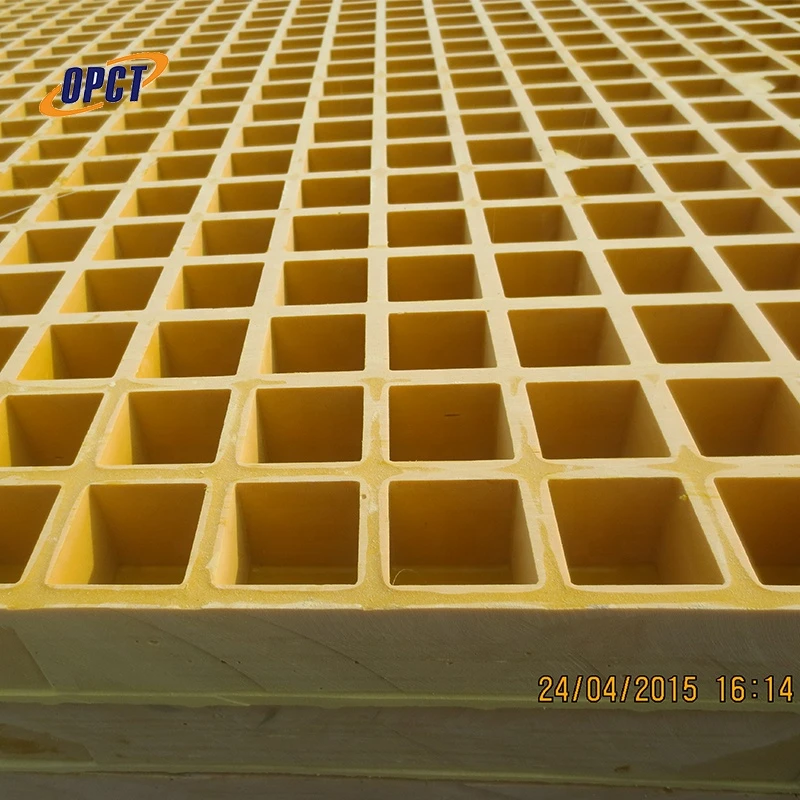

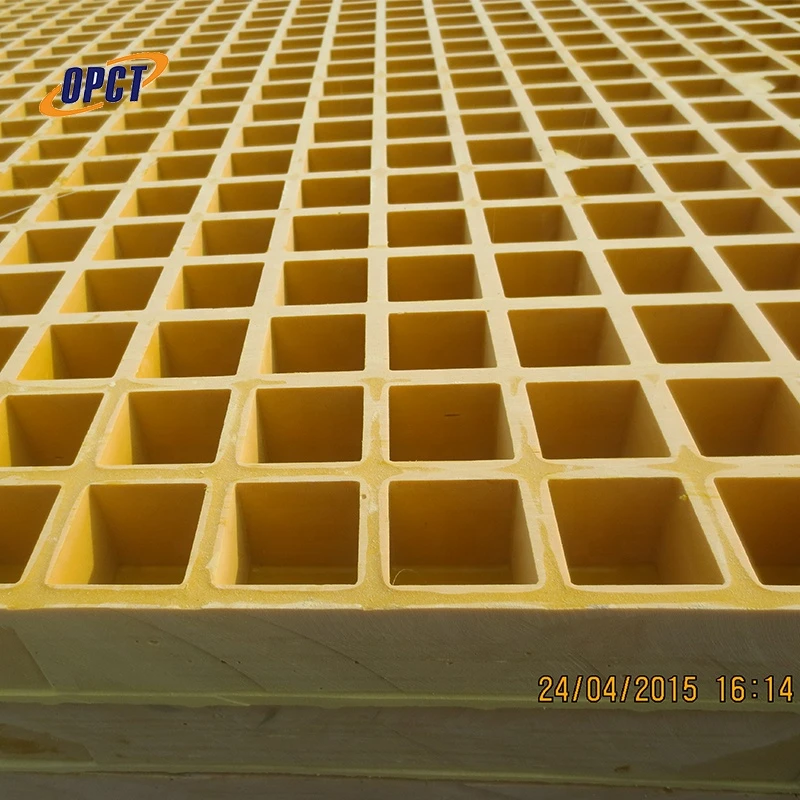

pure iron nails factories

Trustworthiness in the pure iron nail industry is built on a foundation of verified quality and compliance with international standards like ISO. Quality assurance teams within these facilities employ rigorous testing methods to verify the tensile strength, shear capacity, and corrosion resistance of the nails. These tests are part of a broader quality control strategy that includes regular audits and third-party inspections to maintain transparency and accountability throughout the production process.

Sustainability is another critical aspect of modern pure iron nail factories. Many have adopted eco-friendly practices, such as recycling water and repurposing waste materials, to minimize their environmental footprint. This commitment to environmental stewardship is not only environmentally responsible but also aligns with the growing consumer demand for sustainably produced products. By incorporating green manufacturing techniques, these factories enhance their reputation and appeal to environmentally conscious customers.

A deep understanding of the varied requirements across different industries enables these factories to offer an array of nail types designed for specific applications. Whether for masonry, woodworking, or specialized industrial uses, pure iron nails can be customized to meet precise specifications, offering tailored solutions that cater to unique project needs. This adaptability is a testament to the factories' capability to respond to a dynamic market landscape, solidifying their position as industry leaders.

In conclusion, pure iron nails factories are not merely production facilities; they are hubs of innovation, technology, and trust. By prioritizing quality, investing in modern manufacturing processes, and committing to sustainable practices, these factories ensure they remain competitive and reliable suppliers in the global market. Customers can confidently rely on these experts for products that deliver on promises of strength, durability, and environmental responsibility, reflecting the factories' comprehensive and authoritative approach to manufacturing.