In the ever-evolving landscape of industrial manufacturing, acquiring the right pultrusion equipment can significantly boost productivity, ensuring both efficiency and quality in production. Pultrusion, a manufacturing technique used to produce continuous lengths of fiberglass-reinforced plastic profiles, owes much of its success to advancements in the equipment that carry out the process. Whether you're a seasoned manufacturer looking to expand your capabilities or a newcomer to the field, understanding the ins and outs of pultrusion equipment is crucial for achieving operational excellence.

When selecting pultrusion equipment, it’s essential to consider several key factors that denote experience and expertise in the field. Firstly, the equipment's capacity to handle various resin types and reinforcement materials should align with your production requirements. Modern pultrusion machines are designed to accommodate an array of resins, including polyester, vinyl ester, and epoxy, each offering distinct advantages in terms of strength, durability, and application suitability. Expert operators know that choosing the right combination of resins and fibers can significantly influence the final product's properties.

Furthermore, the automation level of the pultrusion equipment plays a pivotal role in manufacturing efficiency. Advanced systems boast automated controls that enhance precision and reduce the likelihood of errors, thereby maximizing throughput while minimizing waste. Equipment featuring sophisticated control systems can accurately monitor and adjust parameters such as pull speed, resin impregnation levels, and curing conditions. This precision is particularly crucial in maintaining consistent quality across large production batches, which authoritative sources in quality management emphasize as a foundation for sustained business success.

Authoritativeness in the realm of pultrusion equipment is also reflected in the supplier's ability to offer customized solutions. Leading manufacturers of pultrusion machines provide tailored configurations that cater to specific customer needs, whether it's adjusting to a unique production scale or integrating additional features for specialized applications.

The ability to customize equipment to fit niche markets reflects a deep understanding and authoritative stance within the industry. Suppliers who offer robust after-sales support, including training, maintenance, and quick procurement of spare parts, further enhance their credibility and reliability.

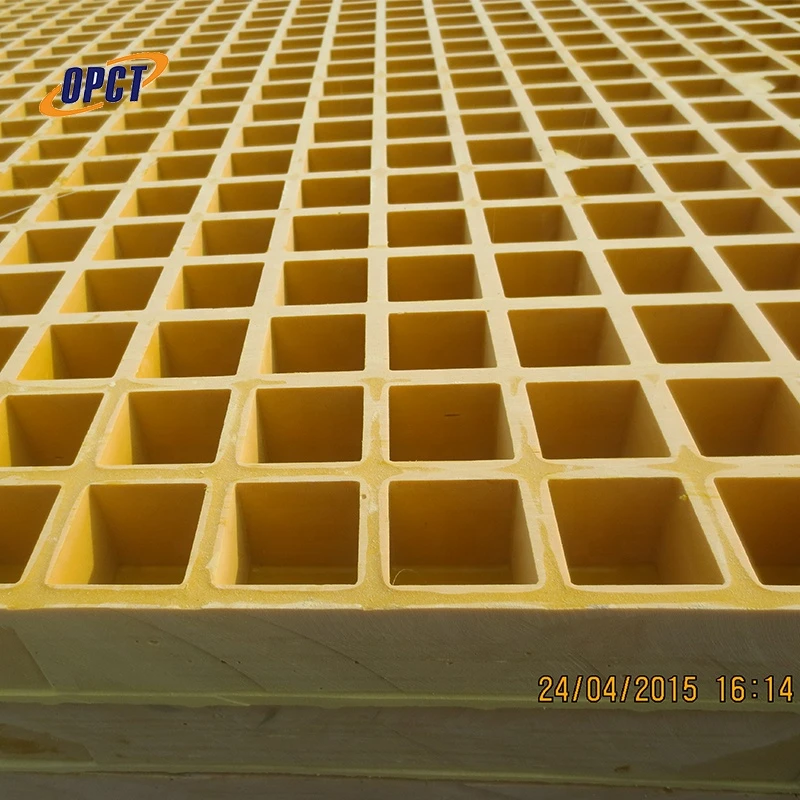

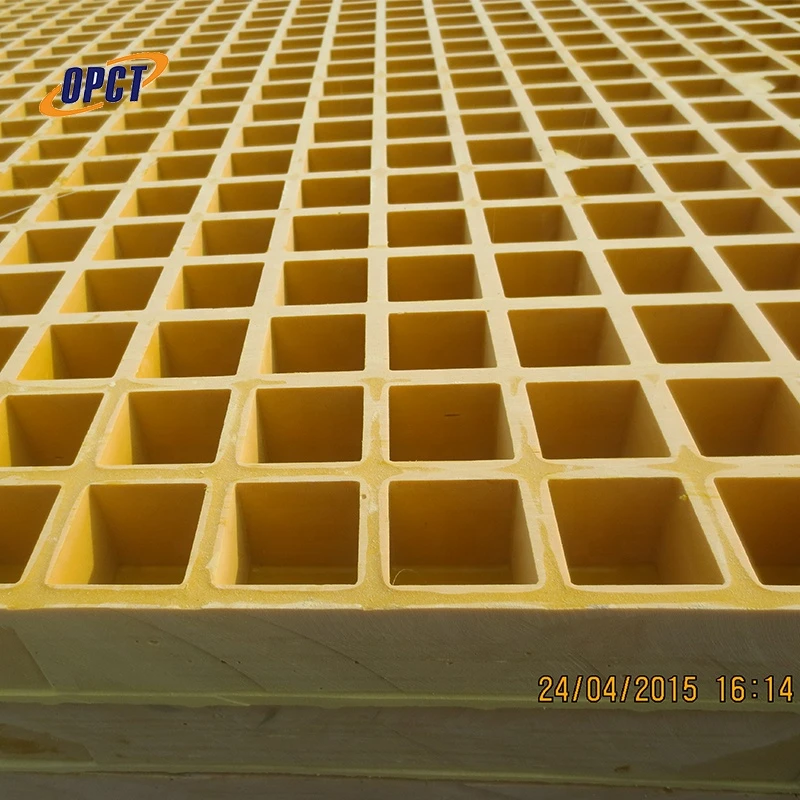

pultrusion equipment

Trustworthiness in pultrusion equipment is often measured by the safety features integrated into the machinery. Equipment that adheres to international safety standards not only protects workers but also ensures compliance with regulatory requirements. Look for machines equipped with safety guards, emergency stop buttons, and comprehensive monitoring systems that give real-time feedback on the equipment's performance and safety status. A trustworthy supplier will have a proven track record of implementing these critical features to ensure the operator’s safety and the equipment’s longevity.

In the context of cost-efficiency and operational scalability, it’s imperative to adopt a long-term perspective. While initial investment costs can be significant, the longevity and durability of high-quality pultrusion equipment justify the expense. Additionally, energy-efficient models contribute to reducing operational costs, making them an appealing choice for companies aiming to balance performance with sustainability. Experienced manufacturers understand the importance of evaluating the total cost of ownership, factoring in not just the purchase price, but also the expected lifespan, maintenance expenses, and energy consumption.

Investing in premium pultrusion equipment often comes with the added benefit of innovation. With industry leaders continuously pushing the boundaries of technology, adopting state-of-the-art equipment can give companies a competitive edge. Innovation-driven features such as advanced resin mixing systems, precise temperature control units, and adaptive die technologies set pioneering companies apart, ensuring they remain at the forefront of the industry.

In conclusion, selecting the right pultrusion equipment is a strategic decision that demands careful consideration of experience, expertise, authoritativeness, and trustworthiness. By focusing on these four pillars, companies can enhance their production capabilities, ensure product quality, and maintain a competitive advantage in the marketplace. As the industry progresses, those who prioritize investing in high-caliber pultrusion equipment will undoubtedly reap the benefits of improved efficiency, safety, and innovation.