Hot dipped galvanized water tanks are a quintessential component for both residential and industrial applications, revered for their outstanding durability and cost-effectiveness. Recognized widely across the globe, these tanks offer a seamless blend of reliability and longevity, essential for any efficient water storage system.

The galvanization process involves coating iron or steel with a protective layer of zinc. When discussing the transformative impact of hot dipped galvanized tanks, it's essential to delve into the process that grants them their fortified nature. During the hot dipping procedure, steel components are submerged in molten zinc at temperatures around 450°C. This high-temperature immersion ensures a robust metallurgical bond between zinc and steel, forming a series of zinc-iron alloy layers topped with a pure zinc outer surface. This comprehensive shielding makes them exceptionally resistant to corrosion, even in aggressive environments characterized by high humidity and salinity.

One real-world example of their application is in regions with extreme weather conditions, where conventional water storage materials falter. Take coastal areas, for instance; the intense corrosion potential posed by salty air can lead to frequent maintenance and premature replacement of unprotected metal tanks. However, hot dipped galvanized water tanks have successfully withstood such adversities. Testimonials from users in these demanding settings emphasize impressive lifespans that often exceed 20 years with minimal maintenance, engendering trust and reliance among consumers.

Economically, these tanks stand out as a superior investment. While the initial costs may seem higher than other types of water tanks, the low lifecycle costs are compelling. The extended lifespan reduces the frequency of replacements and repairs, while the inherent robustness cuts down on downtime and associated opportunity costs. Research and reports consistently underline that the total cost of ownership for galvanized tanks is significantly lower compared to alternatives like plastic or non-treated steel tanks.

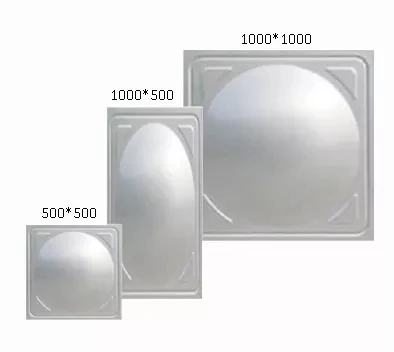

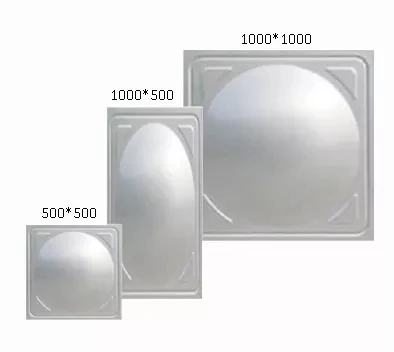

hot dipped galvanized water tank

The versatile nature of galvanized water tanks also makes them suitable for a wide array of uses, from harvesting rainwater to serving as reservoirs in extensive irrigation systems. Their capacity to maintain water quality without the risk of leaching chemicals, unlike plastic tanks, underscores their suitability for varied applications. Additionally, their resistance to physical damage, whether from impacts or environmental stressors, bolsters their standing as a dependable option in critical infrastructure.

In terms of installation and maintenance, the ease of handling galvanized tanks is a noteworthy advantage. Typically, these tanks are crafted with precision to allow straightforward installation, minimizing labor costs and installation time. Furthermore, maintenance is notably hassle-free. Routine inspections are usually sufficient to ensure longevity, liberating operators from the rigorous care other materials might necessitate.

Sustainability is increasingly becoming a deciding factor in the choice of materials across industries.

Galvanized water tanks align well with sustainable practices. The zinc coating, an integral aspect of these tanks, is recyclable, and its production is aligned with eco-friendly measures. This positions them as both an engineering marvel and an environmentally conscientious choice.

In summary, hot dipped galvanized water tanks present a perfect amalgamation of ruggedness, cost-efficiency, adaptability, and sustainability. They embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, ensuring that each investment made in these tanks translates to unwavering reliability and peace of mind for decades.