GRP (Glass Reinforced Plastic) tubes are rapidly becoming a cornerstone in industries that demand high-performance and durable materials. Companies in sectors such as water treatment, oil & gas, and civil engineering are increasingly turning to GRP tubes due to their superior properties that outshine traditional materials like steel and concrete. As an SEO expert and industry analyst, I’m here to delve into why GRP tubes are a game-changer and how they can solve some of the most pressing challenges in these domains.

Experience speaks volumes when assessing the practicality and efficiency of any material. GRP tubes have a track record of excellent performance in harsh environments where other materials fall short. For instance, in wastewater management facilities, where the chemical composition can be exceedingly corrosive, GRP tubes exhibit incredible resistance, ensuring longevity and reducing the need for frequent replacements. An engineer working in a desalination plant noted that since switching to GRP tubes, maintenance periods have been significantly extended, allowing the plant to function efficiently with less downtime and lower maintenance costs.

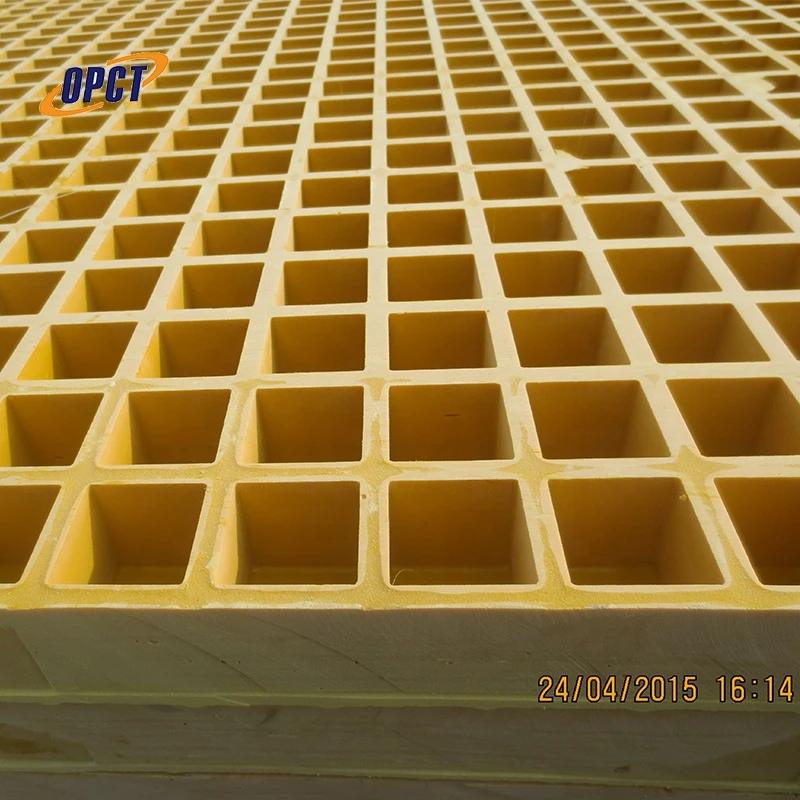

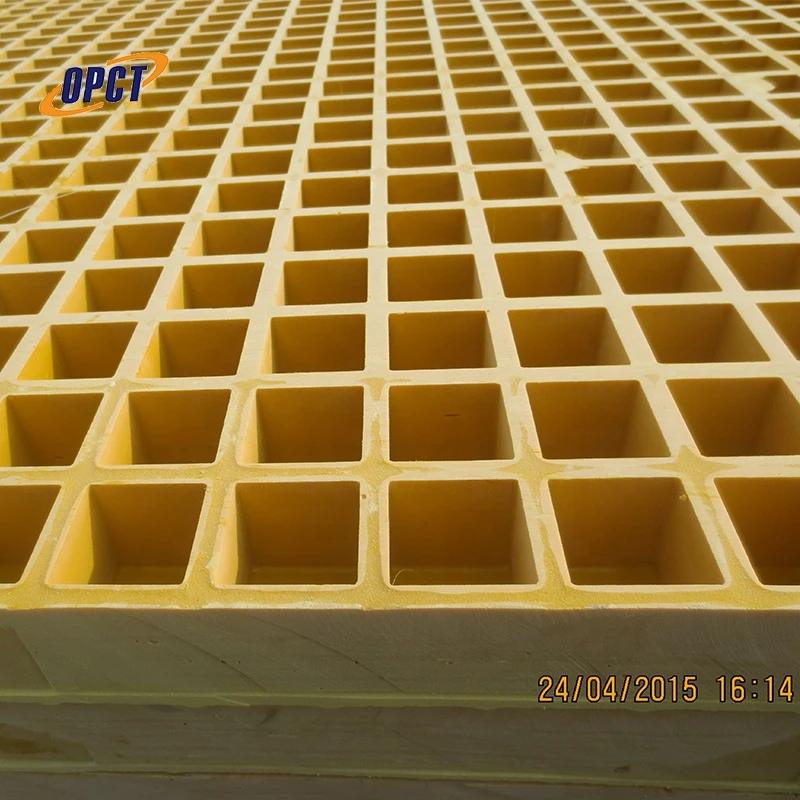

In terms of expertise, understanding the composition and structure of GRP tubes is essential. Composed of fiberglass and a polymer matrix, GRP tubes offer minimal risk of corrosion, a prevalent issue in metal tube counterparts. Through innovative engineering, GRP is molded to create tubes with unsurpassed strength-to-weight ratios. This advancement not only enhances ease of installation but also contributes to cost savings in transport and installation time. Industry professionals recognize this engineered solution as a right fit for modern infrastructure challenges, where lightweight yet robust materials are increasingly prioritized.

grp tube

When discussing authoritativeness, it is crucial to note the certifications and standards that GRP tubes meet globally. From ISO standards to ASTM certifications, GRP tubes comply with rigorous international benchmarks that assure stakeholders of their reliability and effectiveness. Leading industry bodies, such as the American Water Works Association, have included GRP tubes in their directives for modern water systems, reflecting industry-wide acknowledgment of their superior qualities.

Trustworthiness is crucial for any product, especially those used in critical applications such as infrastructure and utilities. GRP tubes have been subjected to extensive testing, which includes exhaustive checks for impact resistance, pressure endurance, and chemical exposure, among others. A specific case study from an oil field in Saudi Arabia documented how GRP pipelines maintained integrity despite exposure to oil, gas, and harsh environmental conditions over a decade of use. This not only demonstrates GRP tubes' resilience but also enhances confidence among engineers and project managers considering their application for long-term projects.

In conclusion, GRP tubes represent a significant advancement in materials science, offering unmatched benefits over traditional alternatives. Their corrosion resistance, strength-to-weight ratio, compliance with international standards, and proven track record in various industrial applications underline their growing preference among industry professionals. Whether in the fast-paced oil and gas sectors or the critical infrastructure of urban planning, GRP tubes provide an innovative and sustainable solution that meets contemporary needs. Investing in GRP technology not only yields immediate benefits in terms of performance and cost efficiency but also aligns with a future-focused approach toward sustainable and resilient infrastructure development.