Fiberglass Reinforced Plastic (FRP) tanks, commonly referred to as grp tanks, have revolutionized the way industries store and handle liquids. With their superior strength-to-weight ratio, corrosion resistance, and flexibility in design, grp tanks have become indispensable across various sectors including chemical, water treatment, and food and beverage industries.

The expertise required in manufacturing grp tanks plays a significant role in their effectiveness and longevity. Utilizing the latest advancements in polymer technology, manufacturers ensure that these tanks meet the rigorous demands of modern storage needs. Exclusive resin formulations are used to reinforce fiberglass layers, leading to tanks that exhibit excellent resistance against aggressive chemicals, UV exposure, and temperature fluctuations.

This expertise not only enhances the physical properties of the tanks but also their durability.

Trustworthiness in grp tank design and usage cannot be overstated. Before reaching the market, each tank undergoes comprehensive testing and certification processes to ensure compliance with international safety and quality standards. Leading manufacturers invest heavily in research and development, implementing state-of-the-art testing protocols that simulate real-world conditions. This guarantees that the tanks perform optimally even under extreme conditions, a crucial consideration for industries that cannot afford system failures.

Furthermore, real-world experience from industries using grp tanks reinforces their standing as a reliable storage solution. Many facilities have reported significant reductions in maintenance costs due to the tanks' inherent corrosion resistance. Unlike traditional metal tanks that require frequent recoating or replacement, grp tanks maintain their structural integrity over extended periods, proving their cost-effectiveness. Case studies highlight industries that have switched from conventional materials to grp tanks and witnessed not only financial savings but also operational efficiency improvements.

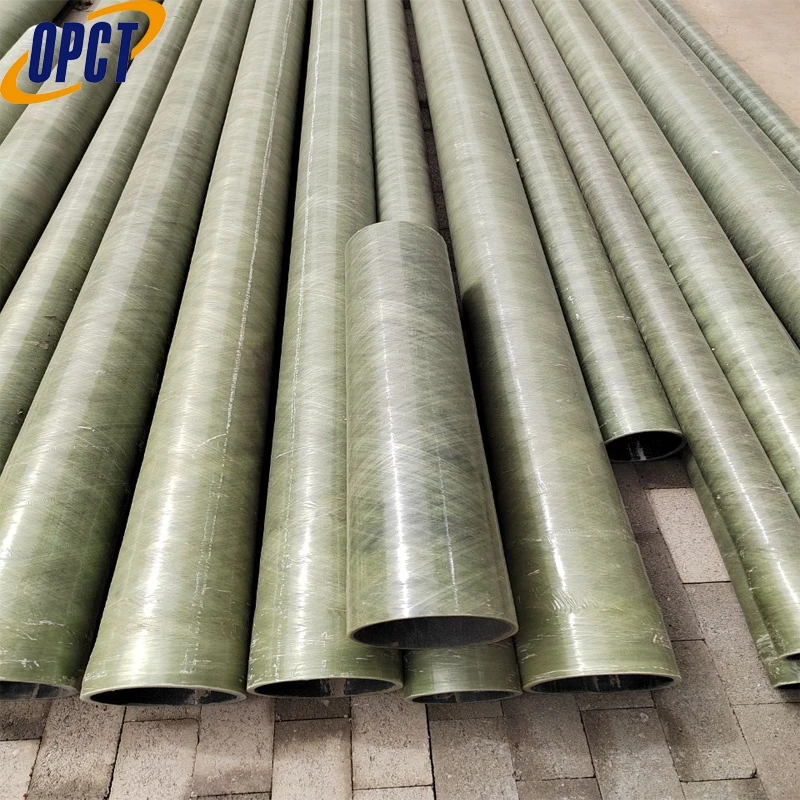

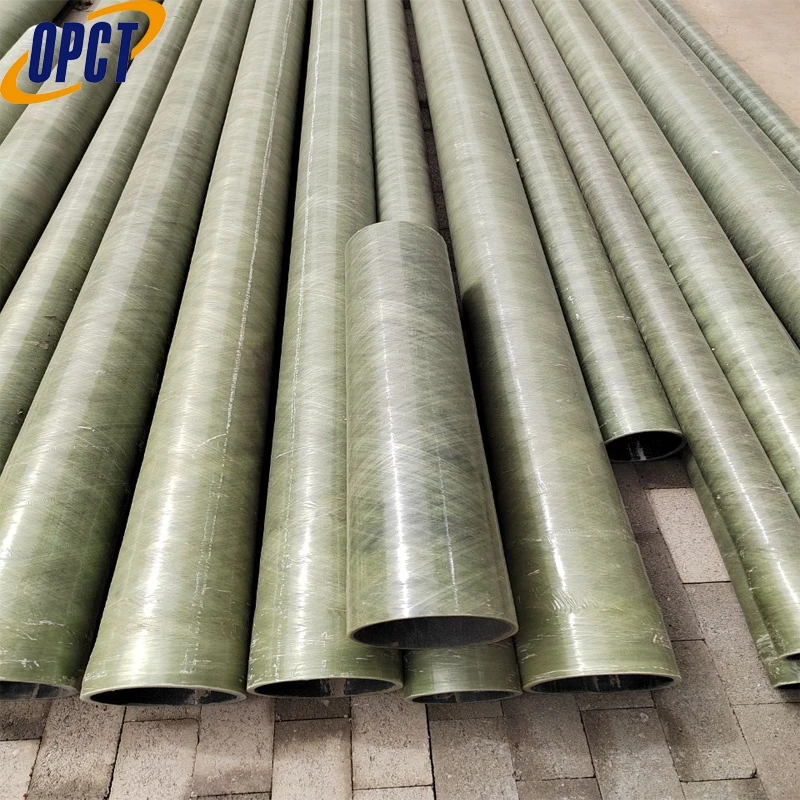

grp tank

Authoritativeness is exhibited by the manufacturers through their commitment to innovation and customer satisfaction. Leading brands often employ seasoned engineers and materials scientists who continually push the boundaries of grp tank design. By partnering with clients to tailor solutions that meet specific requirements, these manufacturers establish themselves as authoritative figures in the storage tank industry. Their continuous feedback loops and adaptability to industry changes ensure that they remain at the forefront of grp tank technology.

For businesses looking to invest in grp tanks, confidence in their credibility is bolstered by the long track record of successful installations worldwide. These tanks have supported small-scale operations to large industrial complexes, each case adding to a repository of positive testimonials. The transparency of leading manufacturers regarding their manufacturing processes and material compositions further augments customer trust.

In conclusion, grp tanks represent the pinnacle of modern storage solutions, combining experience, expertise, authoritativeness, and trustworthiness. Their unparalleled performance has been consistently validated by extensive research and practical applications, making them the preferred choice for industries seeking reliable and sustainable storage options. With ongoing technological advancements and a firm foundation of customer satisfaction, grp tanks are poised to meet the ever-evolving demands of global storage needs.