Glass Reinforced Plastic (GRP) gratings, often referred to as fiberglass gratings, have gained significant attention in the industrial sector due to their versatile properties and applications. A deeper understanding of these products unveils their unparalleled advantages and potential uses across various settings, firmly establishing GRP grating as a prime choice for many industries.

Constructed from a composite of robust fiberglass and a resin matrix, GRP gratings stand out for their exceptional strength-to-weight ratio. This unique construction renders them not only lightweight but also remarkably durable, offering resistance to a wide array of chemicals. This resistance makes them an optimal choice for environments where exposure to corrosive substances is common, such as chemical plants and wastewater treatment facilities. Unlike traditional metal gratings, they do not rust or corrode, reducing the need for frequent replacements and ensuring long-term reliability.

In the realm of safety, GRP gratings take precedence, providing slip resistance that surpasses that of metal alternatives. Their anti-slip characteristics are crucial in settings where moisture, oil, or icy conditions may pose a hazard. Furthermore, they are non-conductive to heat and electricity, making them ideal for areas where electrical safety is a concern. Industries ranging from oil and gas to marine utilize GRP gratings to enhance workspace safety due to these intrinsic qualities.

The ease of installation associated with GRP gratings cannot be overstated. Their lightweight nature not only reduces transportation costs but also simplifies the installation process, often eliminating the need for heavy machinery. Maintenance is equally straightforward, involving minimal effort to retain their structural integrity and appearance. This ease of handling translates to considerable cost savings over time, making GRP gratings a cost-effective solution.

The adaptability of GRP gratings further expands their applications. Available in a variety of panel sizes, thicknesses, and colors, they can be customized to meet the specific requirements of any project. Their ability to be cut to size without compromising structural integrity affords contractors and engineers the flexibility to implement them in a diverse array of industries including architecture, food processing, and mining.

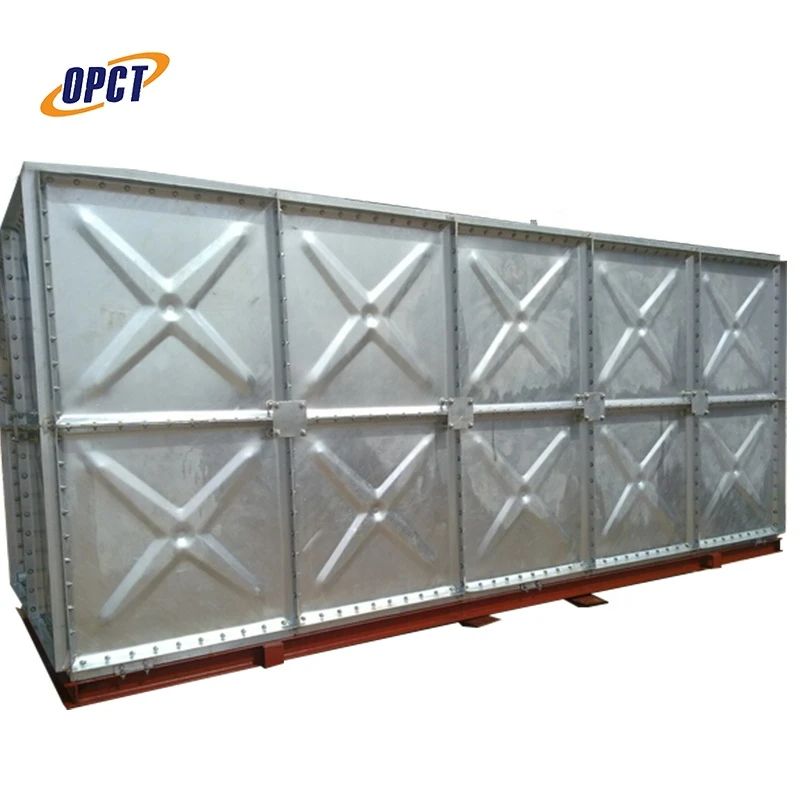

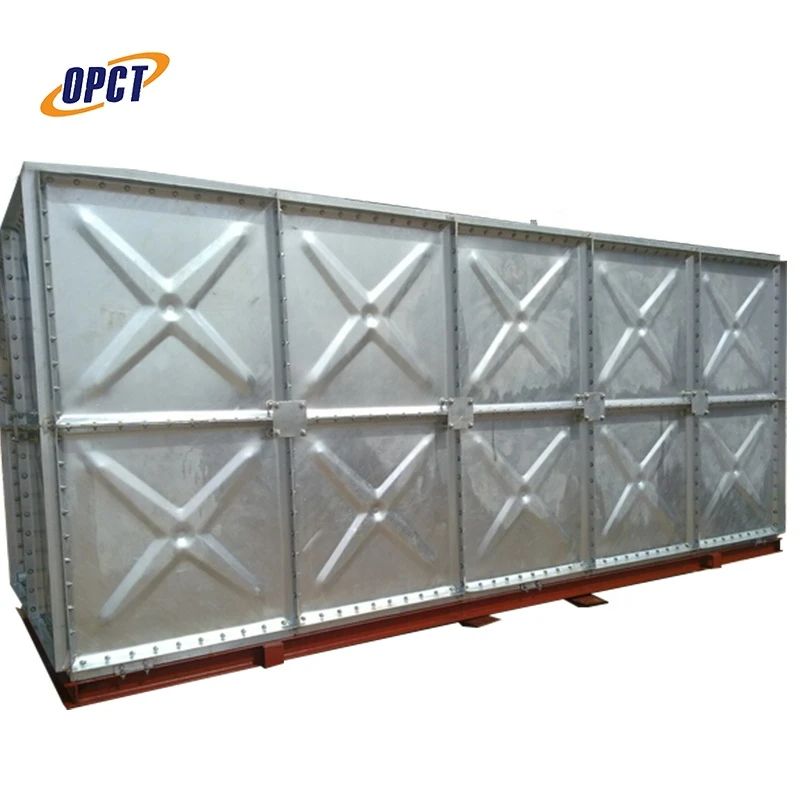

grp grating

Their eco-friendly nature also boosts their appeal. GRP gratings are made from materials that do not emit harmful toxins, supporting sustainable practices across industries. Additionally, the long lifespan and reduced need for replacements mean fewer materials are required over time, lessening the environmental impact associated with production and disposal.

Endorsed by industry experts for their performance and reliability, GRP gratings are backed by extensive research and real-world applications. Case studies have demonstrated their ability to outperform traditional materials under rigorous conditions. For instance, in coastal regions where saltwater corrosion is prevalent, GRP gratings have demonstrated superior performance over metal gratings, maintaining their integrity longer and reducing downtime caused by maintenance.

The trustworthiness of GRP gratings is underpinned by compliance with strict industry standards, which guarantee the quality and safety of these products. Recognized certifications provide assurance to clients that GRP gratings adhere to the highest industry benchmarks, reinforcing confidence in their use for critical applications.

In conclusion, the advantages of GRP grating, encompassing durability, safety, ease of installation, and environmental benefits, position them as a forward-thinking choice for industrial applications. Their adaptability to varied and challenging conditions highlights their role as an indispensable element in the infrastructure of tomorrow. For industries seeking a reliable and sustainable solution, GRP grating offers an unmatched combination of expertise, authority, and trustworthiness.