In an era where environmental sustainability has become a global priority, innovations in recycling and material repurposing have gained significant traction. Among these innovations is grate plastic, a term that represents a breakthrough in recycling technology and environmental management.

Grate plastic refers to a method of recycling plastic waste into durable materials that can serve various practical applications. Unlike typical recycling processes, which often degrade the quality of plastic, grate plastic technology preserves and, in some cases, enhances its characteristics, creating an even more resilient material.

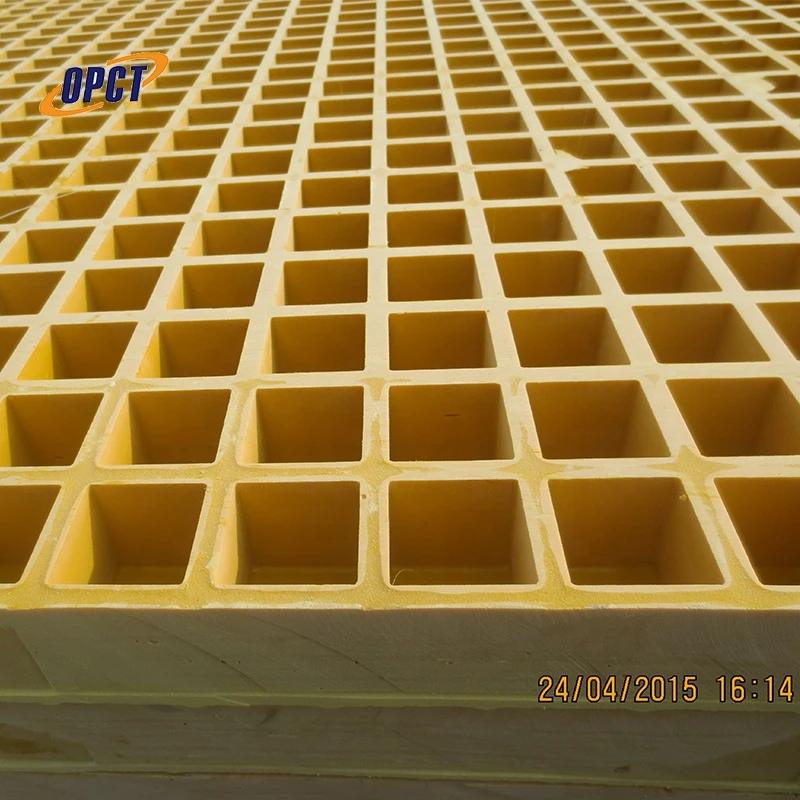

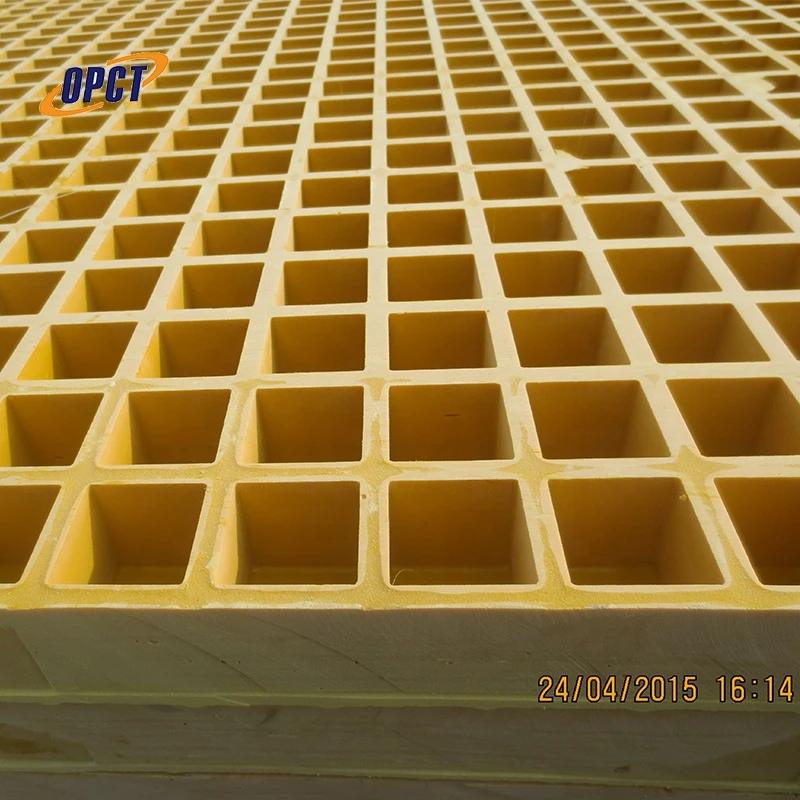

Through meticulous research and development, engineers have advanced grate plastic to a level of expertise that sets new standards for recycled materials. The process begins with collecting high-density polyethylene (HDPE) and polypropylene (PP) plastics, commonly used in consumer goods and packaging. These plastics are rigorously cleaned and sorted, ensuring optimal purity before undergoing the grate process, where they are mechanically and chemically treated to bind and reform them into a solid, stable structure.

The expertise involved in creating grate plastic lies in its ability to meet or exceed the physical properties of original polymers. This is achieved through patented methods that involve cross-linking the polymer chains, resulting in a final product that is not only exceedingly strong but also resistant to UV rays and various chemical exposures. It is this unique blend of durability and versatility that positions grate plastic as a material of choice across numerous industries.

For example, in the construction industry, grate plastic is being increasingly utilized for the production of robust exterior decking, barriers, and structural support systems. Unlike wood, grate plastic does not warp or splinter, offering significant advantages in longevity and maintenance. Its weather-resistant properties make it particularly suitable for outdoor uses, where it can withstand environments that would typically degrade traditional construction materials.

grate plastic

Moreover, grate plastic has transformed transportation solutions, finding applications in automotive components and urban infrastructure. Its lightweight yet sturdy nature helps reduce vehicle weight, improving fuel efficiency and reducing carbon emissions. Additionally, as a cost-effective alternative to virgin plastics, grate plastic supports a circular economy, reducing the raw material extraction and promoting resource conservation.

Authoritative research supports the trustworthiness of grate plastic as an environmentally sound choice. Studies published in leading material science journals underscore its superior lifecycle assessment compared to other recycled products. Additionally, because the production process for grate plastic uses significantly less energy than manufacturing new plastic materials, it substantially decreases the carbon footprint associated with plastic production.

The commitment to transparency and environmental stewardship further instills confidence in its credibility. Transparency in production practices and certifications from environmental agencies verify that grate plastic meets global sustainability standards, reinforcing its position as a responsible ecological choice.

Ultimately, the rise of grate plastic underscores a pivotal shift towards utilizing innovative materials to combat environmental challenges. By combining experience, expertise, and trustworthiness, this breakthrough has not only secured a noteworthy place in the sustainable materials market but also paved the way for future advancements in eco-friendly technologies. As industries continue to prioritize sustainability, grate plastic stands out as a testament to the power of innovation in fostering a more resilient and responsible world.