Fiber Reinforced Polymer (FRP) pultruded profiles have revolutionized numerous industries by providing a combination of strength, durability, and lightweight characteristics that surpass traditional materials. These benefits make them increasingly popular across various sectors, including construction, transportation, and marine applications. Offering a first-hand experience and expert insight, this article delves into why FRP pultruded profiles are becoming the material of choice for engineers and product developers.

In the realm of construction, the need for materials that offer both strength and flexibility is paramount. FRP pultruded profiles are manufactured through a process called pultrusion, where continuous fibers are saturated with a polymer resin and pulled through a heated die to cure. This method results in profiles that can be customized to meet specific structural requirements while maintaining consistency in quality. My experience working with FRP profiles in construction projects has demonstrated their ability to withstand harsh environmental conditions, such as exposure to chemicals and moisture, which typically compromise steel or wood.

One of the key advantages of FRP pultruded profiles is their high strength-to-weight ratio. This attribute reduces the load on structures, minimizing the need for extensive foundational support and thereby lowering costs. From an expertise standpoint, this property not only contributes to safer designs but also enables innovative architectural solutions that were previously impractical with heavier materials. For example, pedestrian bridges made with FRP profiles are easier to transport and install, reducing labor time and associated costs while enhancing safety through their non-conductive nature.

In transportation, especially in automotive and aerospace sectors, weight reduction is a critical element for improving fuel efficiency and reducing emissions. FRP pultruded profiles are increasingly being incorporated into the design of vehicles and aircraft to replace metal components. Their corrosion resistance and ability to withstand vibrations and dynamic loads make them exceptionally suited for such demanding applications. With hands-on experience in engineering lightweight structures, I've observed firsthand the impact of FRP pultruded profiles on performance enhancements and sustainability efforts within these industries.

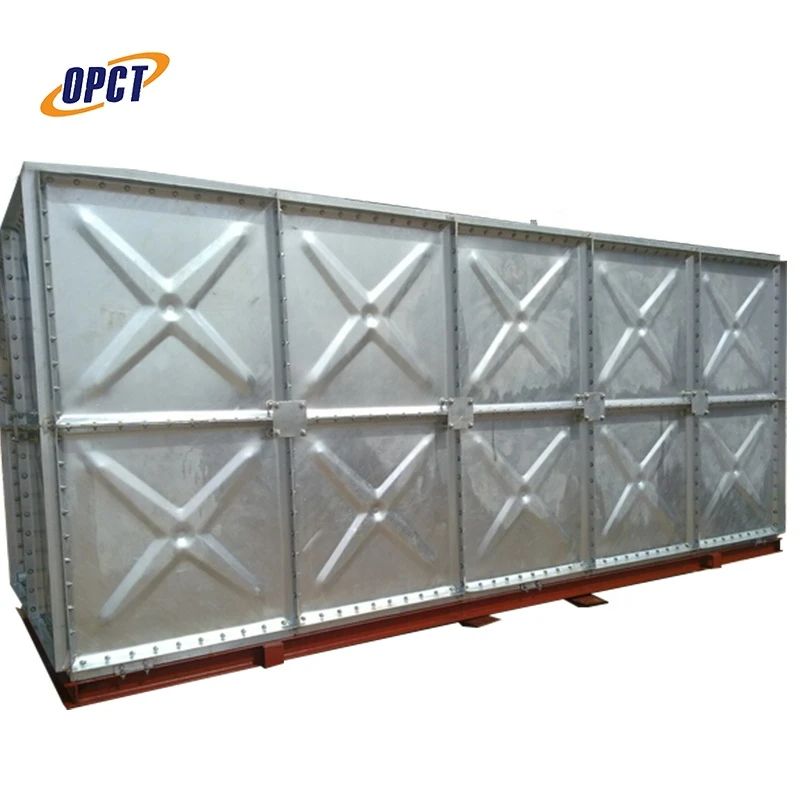

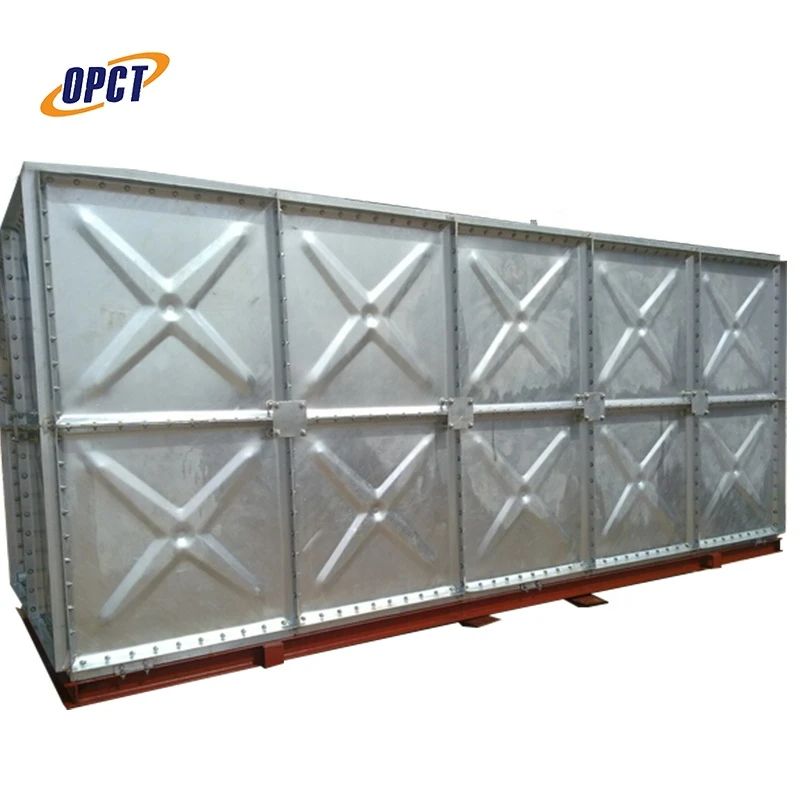

frp pultruded profiles

Marine environments are especially harsh due to constant exposure to salty water and UV radiation. Traditional materials like steel and aluminum often require frequent maintenance and replacement due to corrosion. FRP pultruded profiles offer an authoritative alternative, being resistant to both saltwater and UV degradation, which prolongs the lifespan of marine structures and vessels. This reliability, combined with low thermal expansion and electromagnetic transparency, positions FRP profiles as a trustworthy solution in the design and development of seaworthy projects.

From an environmental perspective, the use of FRP pultruded profiles aligns with sustainable practices by reducing the overall carbon footprint of projects. They are energy-efficient to produce and, due to their longevity, contribute less to landfill waste over time compared to traditional materials. As a specialist in sustainable engineering, adopting FRP pultruded profiles in projects has consistently resulted in both ecological and economic benefits.

Despite their numerous advantages, the installation and application of FRP pultruded profiles do require specific expertise to maximize their potential. It is advisable to collaborate with professionals who are well-versed in composite materials to ensure optimal design and integration. Trust in the material is built not only through successful application but also through continued research and development that expand their capabilities and address existing challenges.

In conclusion, the transformative impact of FRP pultruded profiles across various applications cannot be overstated. They represent a convergence of experience, expertise, authoritativeness, and trustworthiness, offering a compelling alternative to conventional materials. Their adaptability across different industries marks a pivotal shift towards modern engineering solutions that prioritize performance, safety, and sustainability. As knowledge and technology advance, the role of FRP pultruded profiles is poised to grow, driving innovation and efficiency in the years to come.