FRP pipes, or fiber-reinforced plastic pipes, have gained a significant foothold in various industries due to their unmatched advantages over traditional piping materials. Evaluating the price of FRP pipes involves more than just a simple cost-per-foot analysis; it encompasses a comprehensive understanding of the product's lifecycle, benefits, and application-specific expertise.

Over recent years, industries spanning from chemical plants to offshore oil platforms have started to favor FRP pipes due to their exceptional resistance to corrosion, lightweight structure, and impressive longevity. This shift not only indicates their functional superiority but also their cost-effectiveness in the long term. However, prospective buyers are often faced with seemingly high initial costs of FRP piping systems.

It's crucial to delve into what these costs truly represent. The upfront price of FRP pipes often reflects the technical innovation and advanced manufacturing techniques deployed to produce them. From the meticulous selection of raw materials like epoxy, vinyl ester, or polyester resins combined with glass fiber reinforcements to the precision-molding processes, every step is engineered to optimize durability and performance.

For industries that operate under harsh conditions, such as chemical processing facilities where pipelines must resist various corrosive agents, the long-term savings achieved by mitigating maintenance and replacement costs speak volumes about the financial viability of opting for FRP pipes. Traditional materials such as steel may present a lower initial purchase price, but they inevitably incur higher operational costs due to frequent maintenance and corrosion-related failures.

Expertise in selecting the right type of FRP pipe for specific applications is another key factor that influences pricing. Not all FRP pipes are created equal; they vary based on the composition of their resin and fiber reinforcement, which determines their suitability for particular environments. An authoritative supplier with an in-depth understanding of the product and its applications can provide tailored solutions that ensure both performance and cost-efficiency.

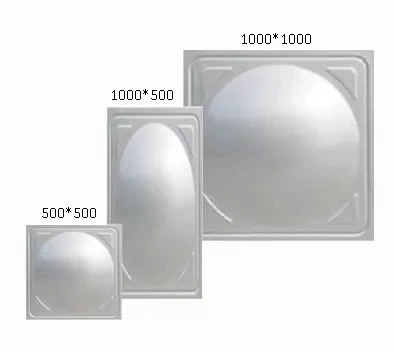

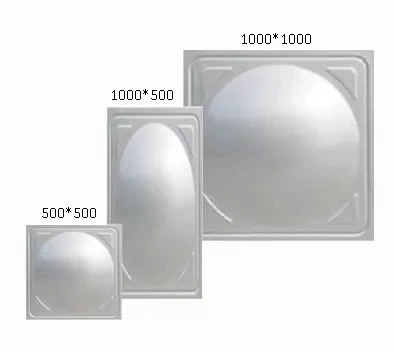

frp pipe price

Trustworthiness in a supplier can further impact pricing and customer satisfaction. Reputable manufacturers and suppliers often offer guarantees or warranties, evidencing their confidence in the product's quality and performance. Additionally, collaborating with an experienced supplier can provide access to valuable advice on installation and maintenance, which is integral to realizing the full value of your investment.

A nuanced view of FRP pipe pricing also requires an appreciation of its lifecycle advantages. While the initial investment might be higher, FRP piping's intrinsic properties such as high strength-to-weight ratio, minimal thermal expansion, and excellent fatigue resistance contribute to prolonged service life, thus negating frequent replacement needs and reducing downtime—factors that substantially cut down cumulative operational costs.

Moreover, sustainability considerations are reshaping purchasing decisions in favor of products like FRP pipes. Their longer lifespan implies a smaller environmental footprint over time compared to traditional materials that necessitate more frequent replacements and contribute to waste. By investing in FRP piping solutions, companies not only benefit financially but also align with global trends towards more environmentally responsible practices.

In conclusion, evaluating the price of FRP pipes requires a blend of financial foresight, expert guidance, and an understanding of material science. These elements combined unveil the true cost-savings and operational advantages of choosing FRP piping systems. By selecting reputable suppliers committed to quality and support, industries can maximize the return on investment while ensuring safety, reliability, and sustainability in their operations.