The increasing demand for FRP (Fiber Reinforced Plastic) pipes in various industries has paved the way for innovative manufacturing techniques, with the filament winding machine being at the forefront. As industries prioritize durability and lightweight materials, understanding the intricacies of an FRP pipe filament winding machine becomes essential for manufacturers and engineers seeking expertise in the field.

At its core, the FRP pipe filament winding machine is an intricate piece of machinery designed to produce highly durable and lightweight pipes by wrapping strands of fiber, typically glass or carbon, soaked in resin around a rotating mandrel. This process, although automated, demands a precise balance of mechanical expertise, material knowledge, and a thorough understanding of the end-use scenarios to ensure optimal results.

One of the primary advantages of using an FRP pipe filament winding machine is its ability to create bespoke pipe dimensions and configurations tailored to specific industry needs. This flexibility is critical in sectors like oil and gas, wastewater management, and chemical processing, where pipe specifications often require customization to withstand variant pressures and chemical exposures. The machine can be programmed to adjust the winding angle and layer thickness, imparting the necessary strength and corrosion resistance required by the application.

In the realm of expertise, the success of using an FRP pipe filament winding machine lies not only in understanding the mechanical nuances but also in selecting the right materials. Engineers and operators must have in-depth knowledge regarding the selection of fibers and resins, ensuring compatibility and longevity of the finished product. Fiberglass, for example, offers high strength and affordability, making it ideal for standard applications, while carbon fiber, despite being more costly, provides superior tensile strength for more demanding environments.

Authoritativeness in this context refers to the manufacturer's capability to consistently deliver quality, which is achieved through the adaptation of cutting-edge technology and adherence to strict industry standards such as ISO and ASTM. Investing in high-quality industrial-grade winding machines equipped with advanced software controls is pivotal. Machines with programmable logic controllers (PLCs) enable precision in winding patterns and tension control, reducing human error and enhancing the integrity of the pipes.

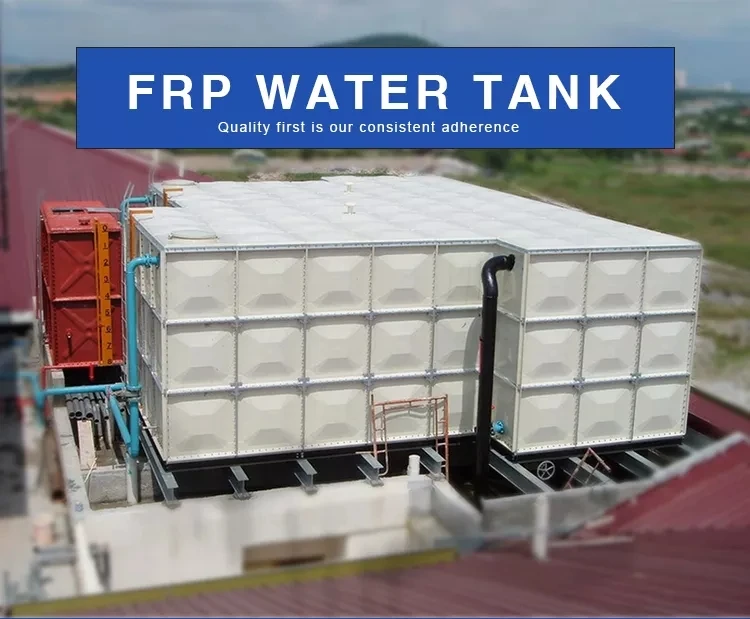

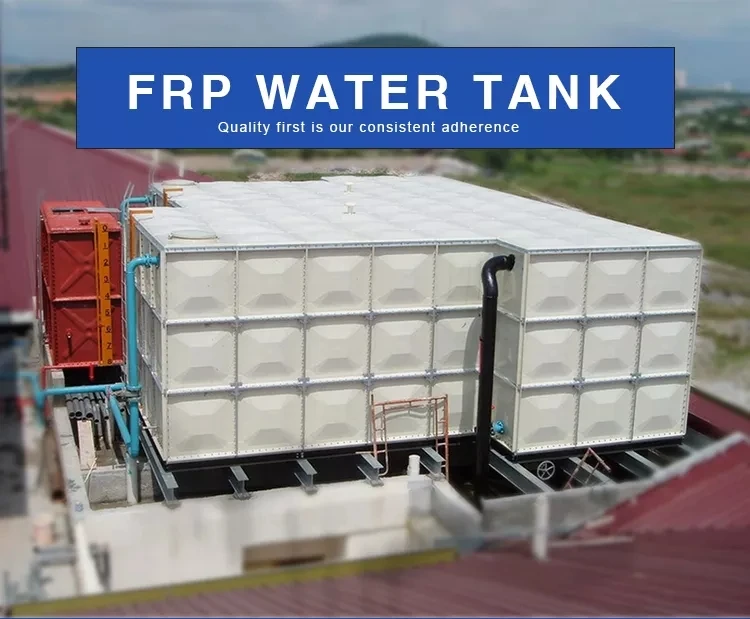

frp pipe filament winding machine

Trustworthiness, particularly for new entrants into the market seeking reliable manufacturers of filament winding machines, can be measured through track records of longstanding partnerships and certifications. Seeking manufacturers that provide comprehensive training for their machines ensures that operators are well-equipped with the skills necessary to maximize the equipment's potential. Additionally, manufacturers that offer ongoing technical support and maintenance should be prioritized, as this reflects their commitment to customer success.

Real-world experience with FRP pipe filament winding machines underscores their utility across diverse applications. For instance, in the oil and gas sector, their implementation has significantly lowered maintenance costs due to the pipes' enhanced resistance to corrosion from harsh chemicals and environmental conditions. Similarly, the transportation industry benefits from the machine's capability to produce lightweight pipes, contributing to reduced vehicle weight and fuel consumption.

For any business contemplating the adoption of an FRP pipe filament winding machine, it is crucial to conduct a thorough cost-benefit analysis, factoring in long-term savings from reduced maintenance and enhanced pipeline performance. Collaboration with experienced professionals in material science and machine operation can further streamline the integration process, ensuring that the transition is both smooth and economically viable.

In conclusion, the FRP pipe filament winding machine stands out as a transformative technology defined by its versatility and precision. Leveraging these machines enables manufacturers to meet stringent industry demands while fostering innovation and efficiency. Experts with a profound understanding of this machinery are at a significant advantage, providing not only superior products but also spearheading advancements in the manufacturing landscape. Prioritizing experience, expertise, authoritativeness, and trustworthiness is vital for anyone aiming to excel in the FRP manufacturing arena.