Understanding FRP Panel Tanks A Comprehensive Overview

Fiberglass Reinforced Plastic (FRP) panel tanks have emerged as a revolutionary solution in various industries, including water storage, chemical processing, and wastewater management. These tanks are constructed from a composite material that combines fiberglass with polymer resins, resulting in a high-durability, lightweight, and corrosion-resistant product. As environmental concerns and the demand for efficient water management solutions grow, FRP panel tanks have found their place as a reliable and sustainable option.

Composition and Characteristics

The fundamental component of FRP panel tanks is the fiberglass, which reinforces the plastic matrix, providing structural strength and durability. The fiberglass is resistant to chemical corrosion, making it an ideal choice for storing a variety of liquids, including aggressive chemicals. The outer layer is typically coated with a UV-resistant layer, enhancing the tank's longevity when exposed to harsh weather conditions.

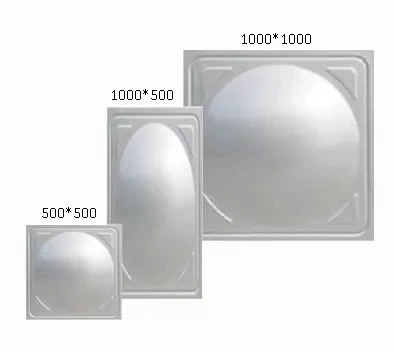

One of the key characteristics of FRP panel tanks is their ability to be manufactured in a variety of shapes and sizes. This adaptability makes them suitable for residential, commercial, and industrial applications. The panels can be assembled on-site, allowing for easy transportation and installation. Furthermore, these tanks often feature modular designs, enabling users to expand capacity as needed.

Advantages of FRP Panel Tanks

1. Corrosion Resistance Unlike traditional metal tanks, FRP panel tanks do not rust or corrode, significantly extending their lifespan. This resistance is crucial in environments where tanks are exposed to harsh chemicals or saline conditions.

2. Lightweight The lightweight nature of FRP makes handling and transport more manageable, reducing installation time and costs. This is particularly beneficial for projects where site access is limited.

3. Maintenance FRP tanks require minimal maintenance compared to other materials. Their smooth surfaces mean there are fewer places for bacteria and sediments to accumulate, making cleaning a straightforward process.

4. Cost-effective While the initial investment may be higher than that of some traditional materials, the long-term savings associated with reduced maintenance, longevity, and efficiency make FRP panel tanks an economically sound choice.

5. Environmental Impact As sustainability becomes a priority for many businesses, the use of FRP panel tanks aligns with eco-friendly practices. They can be produced with recycled materials and help reduce the environmental footprint.

Applications of FRP Panel Tanks

FRP panel tanks are versatile and can be used across a variety of sectors

- Water Storage They are widely used for potable water storage, irrigation, and fire protection systems. Their ability to maintain water quality without leaching harmful substances makes them ideal for this purpose.

- Chemical Storage Industries that handle corrosive substances, such as chemicals and fertilizers, benefit from the robust nature of FRP tanks, ensuring safe storage without the risk of leaks or contamination.

- Wastewater Treatment In wastewater management, FRP panel tanks are employed as clarifiers, aeration tanks, and sludge storage solutions due to their durability and resistance to the harsh chemicals commonly found in waste.

Conclusion

In conclusion, FRP panel tanks are an innovative and practical solution for a range of water management and storage challenges. Their unique properties, combined with their adaptability and sustainability, make them an excellent choice for industries looking to enhance their operational efficiency while minimizing their environmental impact. As technology continues to advance and the need for efficient and reliable storage solutions increases, the role of FRP panel tanks in sustainable infrastructure will become even more significant. Whether for residential, commercial, or industrial applications, FRP panel tanks offer a promising future in the realm of storage solutions.