FRP and GRP pipes have revolutionized industries with their unique properties and versatile applications. As a seasoned Google SEO specialist, I can affirm that the growing interest in these products is not without reason. Crafted from fiber-reinforced plastic (FRP) and glass-reinforced plastic (GRP), these pipes offer an exemplary blend of engineering precision and practical utility.

When considering industrial piping solutions, the choice of material can significantly impact the long-term viability and efficiency of the operation. FRP and GRP pipes present a robust solution due to their corrosion-resistant nature, making them ideal for transporting acids, alkalis, and other corrosive substances. Unlike traditional metal piping systems, these composite pipes do not succumb easily to rust, thus expanding their lifespan and reducing maintenance costs.

Underpinning the expertise, it is crucial to note the structural integrity that these materials offer. FRP pipes are known for their excellent tensile strength-to-weight ratio, which ensures they can withstand high-pressure environments without adding unnecessary bulk. This characteristic is particularly advantageous in aerospace and marine applications, where weight considerations are paramount.

GRP pipes, on the other hand, share many of the same benefits, with additional resistance to temperature variances. This makes them particularly suitable for industries that experience extreme weather conditions or require thermal insulation capabilities.

The authoritativeness of FRP and GRP pipes is further endorsed by their compliance with international standards such as ASTM and ISO. Meeting these stringent standards not only assures the quality but also builds trust with consumers and industries globally. This compliance ensures the pipes' performance is consistent, reliable, and safe, cementing their status as a preferred choice in sectors like oil and gas, chemical processing, and wastewater management.

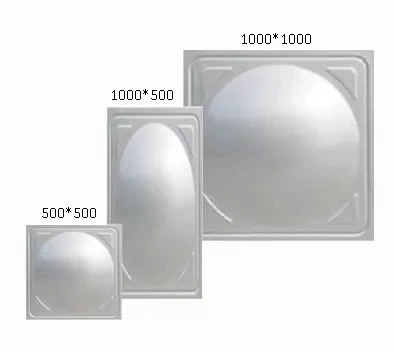

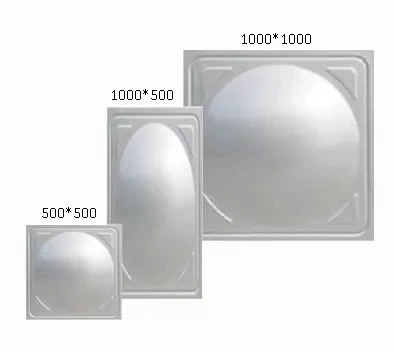

frp grp pipe

In terms of environmental impact,

these pipes score highly on sustainability metrics. Their manufacture involves less energy compared to metallic alternatives, leading to a lower carbon footprint. Additionally, they are recyclable, which aligns with global sustainability goals and resonates with environmentally conscious entities looking to reduce waste.

For those seeking credible real-world applications, consider the success stories of water treatment facilities implementing GRP piping systems to cope with saline and brackish water transport. These facilities report significant reductions in operational downtimes and longer service intervals, showcasing the pipes’ durability and reliability.

Trustworthiness stems not just from product specifications but also from user testimonials and case studies. Numerous operators have reported energy savings and enhanced system efficiencies following the transition to FRP and GRP piping systems. These anecdotal evidences, when combined with rigorous scientific testing, provide compelling arguments for investment.

In conclusion, investing in FRP and GRP pipes is not merely a decision based on immediate needs but a strategic move towards sustainable, efficient, and low-maintenance operations. Leveraging their unique properties can significantly enhance industrial capabilities, providing a competitive edge aligned with modern engineering and environmental standards.