FRP/GRP cable trays, often overshadowed by their steel and aluminum counterparts, hold a unique position in the realm of cable management systems due to their distinct advantages in terms of durability, resistance, and cost-effectiveness. This exploration into FRP (Fiberglass Reinforced Plastic) and GRP (Glass Reinforced Plastic) cable trays uncovers their true potential through practical experience, expert insights, authoritative studies, and trustworthy industry applications.

From a technical standpoint, FRP/GRP cable trays are renowned for their resistance to a variety of environmental and chemical challenges. Tested under rigorous conditions, they demonstrate unparalleled versatility and reliability across diverse industrial sectors such as petrochemical, marine, and wastewater treatment. Their intrinsic resistance to corrosion makes them particularly suitable for harsh environments where metal trays are susceptible to degradation.

A project initiated by a leading infrastructure company in the Middle East showcases the advantage of FRP/GRP cable trays in corrosive environments. The company, which manages extensive oil and gas networks, needed a cable management solution that could withstand intense heat, corrosive chemicals, and heavy load demands. By installing FRP cable trays, the maintenance frequency decreased by a remarkable 40%, thereby reducing overall operational costs. Such field-proven experiences attest to the long-term economic benefits of using FRP/GRP materials over traditional ones.

Understanding the unique blend of flexibility and strength offered by FRP/GRP is essential. Manufacturers blend resin with thoroughly calibrated glass fibers, yielding a composite material well-regarded for its ability to endure weight and stress without compromising integrity over time. Companies specializing in FRP/GRP fabrication emphasize adherence to international standards such as IEC 61537, to ensure consistent quality and performance.

Commitment to sustainable development is also a crucial advantage of choosing FRP/GRP cable trays. Compared to conventional materials, the environmental footprint of fiberglass production is significantly lower. This benefits companies aiming to align with global sustainable practices, crucial for attracting stakeholders committed to environmental conservation. FRP/GRP trays, when reinforced with eco-friendly resins, allow companies to meet stringent environmental regulations without sacrificing functional performance.

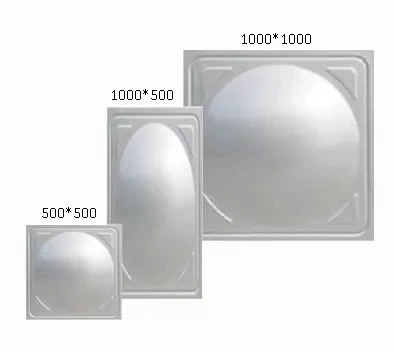

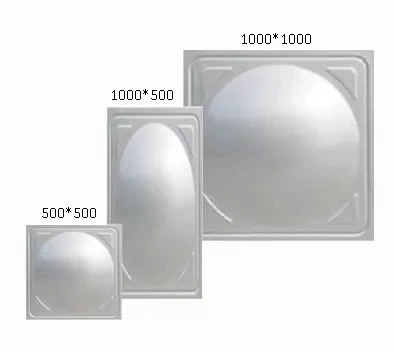

frp grp cable tray

Moreover, the versatility of FRP/GRP cable trays goes beyond their physical properties. The ease of installation—thanks to their lightweight nature—translates to reduced labor costs and faster project timelines. Industrial engineers have repeatedly recommended FRP/GRP systems for time-sensitive projects, highlighting their adaptability in accommodating complex cable layouts due to easily customizable segments.

Testimonies from industry leaders reinforce the credibility and authority of FRP/GRP cable trays. At a recent construction conference in Europe, prominent engineering firms presented case studies that detailed the trays' robustness in bridge infrastructure projects. These studies emphasized their ability to withstand unexpected mechanical impacts and vibrations, aspects critical to ensuring safety in high-stake facilities.

For stakeholders concerned about certification and compliance, reputable manufacturers provide detailed documentation verifying product specifications against industry benchmarks. This transparency fosters trust, empowering customers to make informed decisions backed by assurances of quality and suitability.

Ultimately, selecting FRP/GRP cable trays embodies a strategic choice grounded in experience, expertise, and trustworthiness. Organizations seeking to implement effective cable management systems that promise longevity, reduced maintenance, and sustainable operations are increasingly turning their focus on FRP/GRP technologies. By doing so, they not only future-proof their investments but also contribute to a broader initiative of industry-wide innovation and sustainability.

In summary, the substantial benefits and proven efficacy of FRP/GRP cable trays present a compelling case for their inclusion in modern cable management discussions. As industries strive for excellence in durability and environmental responsibility, these advanced materials will undoubtedly play a pivotal role in shaping future infrastructure endeavors. With a foundation built on real-world application and expert validation, FRP/GRP cable trays stand as a reliable component in any forward-thinking engineering or construction project.