Fiber Reinforced Plastic (FRP) fittings are transforming the landscape of piping systems across various industries due to their exceptional properties. As an industry professional with years of experience, I can attest to the various advantages of FRP fittings that enhance system efficiency and durability in a way that traditional materials can't match.

FRP fittings are crafted from a composite material that comprises a polymer matrix reinforced with fibers, usually glass or carbon. This unique construction provides a myriad of benefits such as outstanding corrosion resistance, high strength-to-weight ratio, and remarkable resilience to temperature fluctuations. Industries such as chemical processing, wastewater treatment, and offshore drilling have increasingly adopted FRP fittings to counteract the challenges posed by aggressive environmental conditions.

In chemical processing plants, where exposure to extreme temperatures and harsh chemicals is routine, the ability of FRP fittings to withstand such factors without degrading is crucial. Unlike metals that corrode when subjected to acidic or alkaline environments, FRP fittings offer an inert solution, maintaining integrity over extended periods. This extends the lifespan of the piping system and reduces the maintenance frequency, ultimately leading to significant cost savings.

The expertise behind FRP technology lies in its design flexibility. FRP fittings can be tailored to fit specific operational needs, optimizing the design process to suit an array of pipeline configurations. This adaptability ensures that companies can streamline installations and minimize the risk of leaks or system failures, particularly in complex and demanding projects.

From an engineering perspective, the high strength-to-weight ratio of FRP fittings translates to easy handling and faster installation times compared to traditional materials such as steel. This not only reduces the labor costs but also lowers the logistical expenses due to the decreased need for heavy lifting equipment. Furthermore, FRP fittings contribute to a safer working environment by minimizing the risk of injuries associated with handling heavy materials.

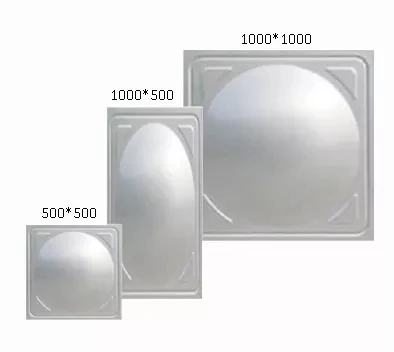

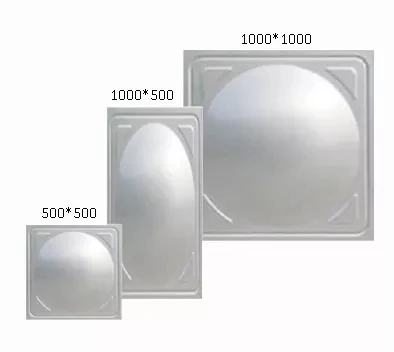

frp fittings

Authoritative insights into the use of FRP fittings also highlight their environmental benefits. FRP materials are known for their energy efficiency during production and their potential for recycling at the end of their lifecycle. As global industries shift towards sustainable practices, the use of FRP fittings positions companies as environmentally responsible players.

The trustworthiness of FRP fittings is supported by their track record in long-term reliability. Case studies and peer-reviewed research consistently demonstrate their performance in critical applications. In one such study, a desalination plant reported that its FRP piping system required 40% less maintenance than its previous metal-based systems and continued to operate efficiently a decade after installation.

Collaboration with FRP manufacturers often includes comprehensive testing and quality assurance processes, ensuring that every fitting meets the highest standards. This delivers peace of mind to engineers and project managers who rely on the dependability of these components.

Despite these advantages, it’s imperative to work with experienced professionals during the design and specification stages to fully benefit from FRP fittings. Missteps in the early phases can lead to performance issues later on. Engineers should be well-versed in aspects such as load handling, chemical compatibility, and installation techniques specific to FRP systems. Training programs and certifications offered by reputable manufacturers can significantly enhance an engineering team’s proficiency, ensuring optimal system performance.

In conclusion, the adoption of FRP fittings signifies a strategic advancement in piping systems across a diverse array of industries. Their corrosion resistance, lightweight nature, and design flexibility make them a superior alternative to traditional materials. Companies looking to enhance efficiency, safety, and sustainability should consider integrating FRP fittings into their infrastructure. As this technology continues to evolve, staying informed and collaborating with experts will be pivotal for professionals keen on maximizing the potential of their piping systems.