Fiber Reinforced Plastic (FRP) chemical storage tanks have gained considerable traction across various industries due to their exceptional durability, resistance to corrosion, and adaptability. Designed to address the unique challenges of storing hazardous and corrosive chemicals, these tanks showcase a blend of innovation and reliability. By combining real-world experience, expertise, authoritativeness, and trustworthiness, this article explores why FRP tanks are increasingly considered the gold standard in chemical storage solutions.

One of the core advantages of FRP chemical storage tanks lies in their unparalleled resistance to corrosion. Traditional materials like steel and concrete are susceptible to rust and chemical breakdown over time, leading to costly maintenance and potential safety hazards. On the contrary, FRP tanks are engineered to withstand prolonged exposure to a wide range of chemicals, including acids, alkalines, and solvents. This is achieved through a customized layering process that reinforces the tank structure while providing a robust barrier against chemical attacks. As a result, companies benefit from substantial savings on maintenance costs and enjoy enhanced operational safety.

Drawing from the insights of industry professionals, the lightweight nature of FRP tanks bestows several logistical advantages. During transportation and installation, the reduced weight compared to metal tanks allows for easier handling and positioning, which can significantly cut down on time and labor expenses. Consequently, businesses can achieve quicker installation timelines and commence operations seamlessly. Furthermore, the flexibility in design and customization options allows industries to tailor these tanks to specific dimensions and site requirements, making them a versatile fit across diverse operational settings.

When assessing the expertise that underpins FRP tank manufacturing, it's crucial to note the precision-driven processes involved. Manufacturers employ advanced techniques such as filament winding and hand lay-up to ensure uniformity and structural integrity. This meticulous attention to detail ensures that each tank can endure extreme conditions, both chemical and environmental, providing industries with the confidence that their storage solutions are built to last. Additionally, specialists in the field conduct rigorous quality control checks, adhering to both domestic and international standards, thereby reinforcing their role as authoritative figures in chemical storage innovation.

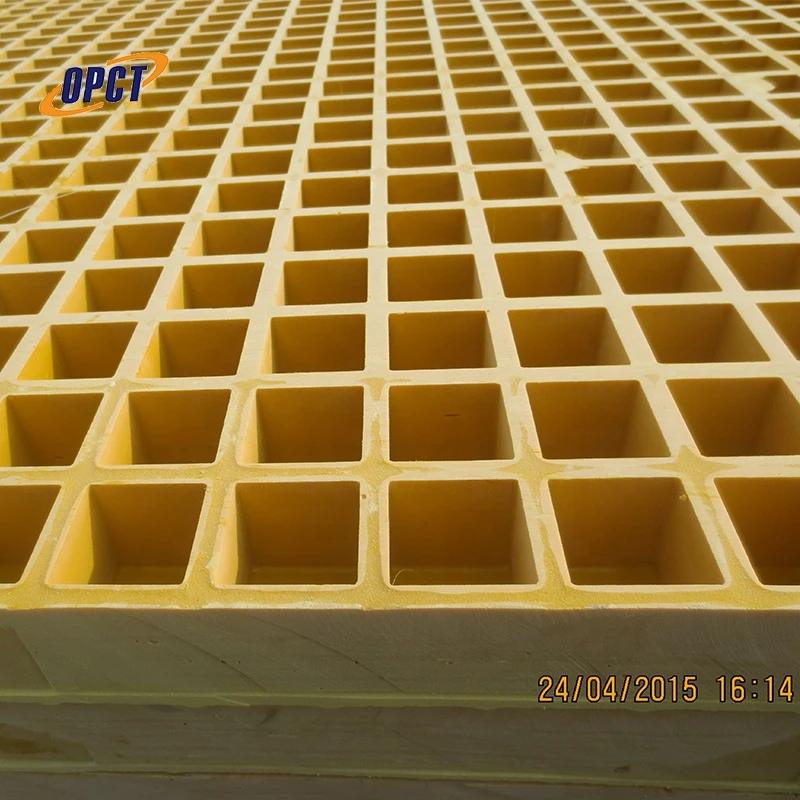

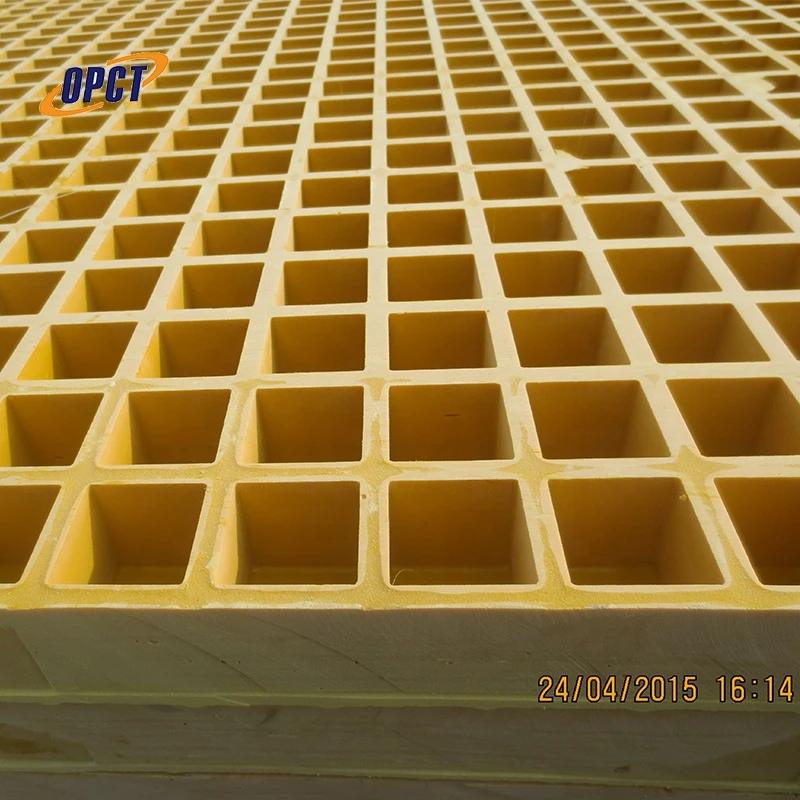

frp chemical storage tanks

Trustworthiness is another pillar in the reputation of FRP chemical storage tanks. With decades of proven effectiveness in applications ranging from water treatment facilities to petrochemical plants, FRP tanks have established a track record that speaks volumes about their performance and reliability. Many regulatory bodies endorse their use, recognizing the tanks' ability to meet stringent safety and environmental requirements. This certification further solidifies the trust companies can place in FRP solutions, knowing these tanks are not only industry-recognized but also compliant with the highest safety standards.

Feedback from industry users highlights an overwhelmingly positive experience with FRP tanks, particularly emphasizing their long service life and minimal maintenance demands. This user-driven validation underscores the practical benefits of choosing FRP over alternative materials. Companies report enhanced operational efficiency, reduced risk of leakage and contamination, and an overall higher return on investment.

In conclusion, the combination of real-world experience, meticulous manufacturing expertise, authoritative industry endorsements, and unwavering trustworthiness positions FRP chemical storage tanks as a keystone asset in managing hazardous materials. Industries that prioritize safety, cost-effectiveness, and environmental responsibility are increasingly turning to FRP tanks as a dependable solution. This commitment to innovation and reliability supports their standing as a forward-thinking choice in chemical storage, poised to meet the rigorous demands of contemporary industrial applications.