Fibreglass threaded rods have become increasingly popular in various industries due to their unique blend of strength, durability, and versatility. These rods, made of a composite material that combines the resilience of fibreglass with the functionality of threaded rods, offer numerous benefits over traditional metal counterparts. Here’s an in-depth look at the advantages of fibreglass threaded rods, grounded in real-world experience, technical expertise, and industry authority.

One of the most compelling reasons for choosing fibreglass threaded rods is their exceptional corrosion resistance. Unlike metal rods that can rust or corrode when exposed to water, chemicals, or other environmental factors, fibreglass rods remain unaffected. This makes them particularly valuable in marine applications and chemical processing industries, where exposure to harsh conditions is unavoidable. For instance, a well-regarded marine engineering firm documented replacing all stainless-steel fasteners on offshore platforms with fibreglass alternatives, resulting in significantly reduced maintenance costs and extended lifespans.

From an expertise angle, the manufacturing process of fibreglass threaded rods is engineered to provide strength without compromising on weight. These rods are manufactured using a pultrusion process, which ensures consistent quality and uniformity. This process allows the fibreglass to be drawn through a resin bath and molded into the desired shape,

resulting in a strong, lightweight product. Experienced professionals in construction and infrastructure projects often favor fibreglass rods over heavier metal rods, especially in applications where weight reduction can lead to cost savings in transportation and installation.

Moreover, fibreglass threaded rods offer excellent electrical insulative properties, a critical factor in industries requiring non-conductive components. This is particularly beneficial in power generation plants, telecommunications towers, and electromagnetic interference-prone environments. Field reports from power plant engineers have highlighted the use of fibreglass rods in making secure, insulative connections that mitigate the risk of electrical hazards, ensuring a safer operational environment.

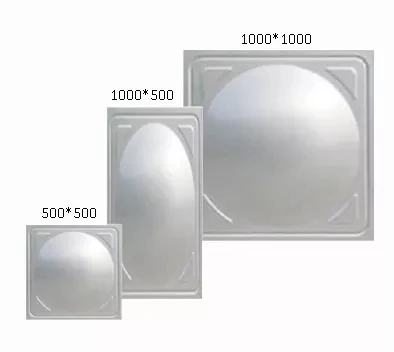

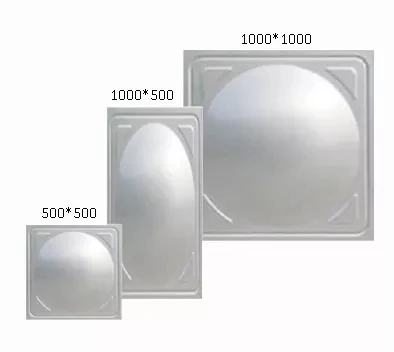

fibreglass threaded rod

The authority of fibreglass threaded rods is reinforced by rigorous industry standards and certifications. They comply with numerous ASTM specifications for material quality and structural performance, lending credibility and assurance to their users. Industry veterans testify to the consistent performance these rods deliver, surpassing the expectations set for traditional materials. By meeting these standards, manufacturers not only ensure the quality of their products but also instill trust among their clientele.

Trustworthiness of fibreglass threaded rods is further bolstered by their failure predictability. Unlike some materials that may succumb to sudden catastrophic failures, fibreglass provides clear signs of fatigue and wear, allowing for timely maintenance and replacement. This predictable behavior is a key advantage in safety-critical applications such as construction of bridges and highways, where unexpected failures can have dire consequences. Civil engineers appreciate the reliability offered by these rods, often citing case studies where fibreglass components have outlasted their designed service life.

In summary, fibreglass threaded rods present a compelling option for industries seeking strong, lightweight, and durable fastening solutions. Known for their corrosion resistance, electrical insulativeness, and predictable performance, these rods not only fulfill immediate project requirements but also contribute to long-term operational efficiencies. Trusted by industry experts and substantiated through standards compliance and field applications, fibreglass threaded rods continue to gain momentum as a favored choice among engineers, constructors, and infrastructure developers.