Fibreglass angles are rapidly becoming a cornerstone material for industries that require durable and lightweight structural components. Unlike traditional materials such as steel or aluminum, fibreglass angles offer a unique combination of flexibility and strength that provides exceptional utility in various applications.

The advent of fibreglass technology has revolutionized construction, especially in environments where exposure to moisture, chemicals, and extreme temperatures is a concern. Fibreglass angles are inherently resistant to corrosion, a critical feature for structural elements in marine, chemical, and industrial applications where metal alternatives might falter. This resilience not only extends the lifespan of infrastructure but also reduces long-term maintenance costs, ensuring reliability and safety.

In addition to their robust physical properties, fibreglass angles are significantly lighter than metal. This reduced weight translates to easier transportation and installation, thereby decreasing labor costs and time on site. Industries have found that this lightweight nature does not compromise strength, as fibreglass angles provide comparable load-bearing capabilities to their metallic counterparts. This strength-to-weight ratio has made them indispensable in projects where structural integrity cannot be compromised but weight is a factor, such as in aerospace and automotive industries.

Fibreglass angles also provide exceptional versatility due to their ease of customization. Manufacturers can modify dimensions, thickness, and even modify the resin systems used to meet specific environmental challenges or regulatory standards. This customization can accommodate both standard and unique project requirements, offering solutions that can be tailored to specific needs. The range of colors available also supports aesthetic considerations in architectural applications, expanding the utility of fibreglass angles beyond functionality alone.

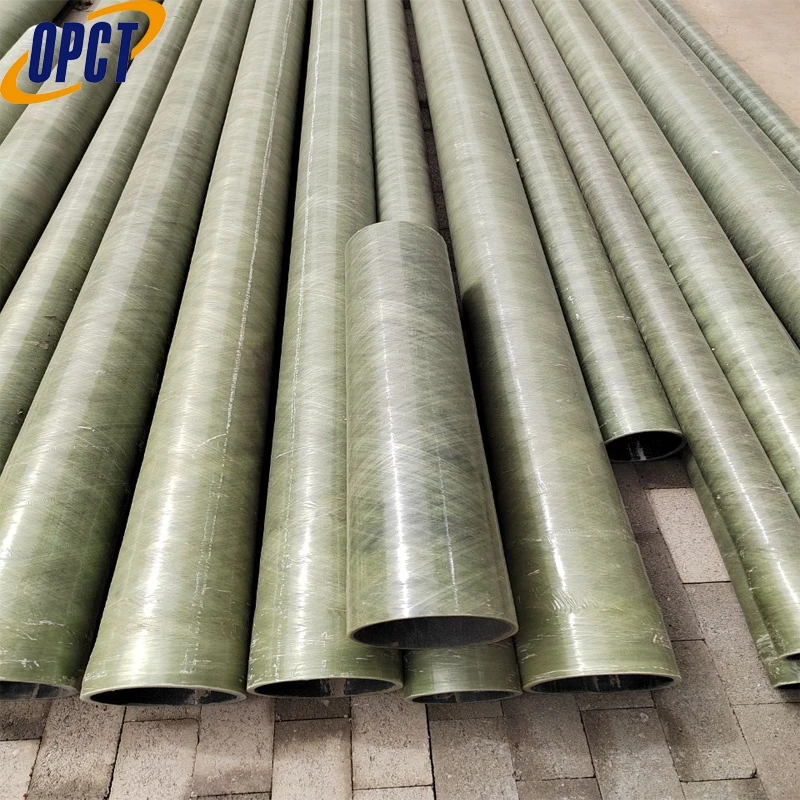

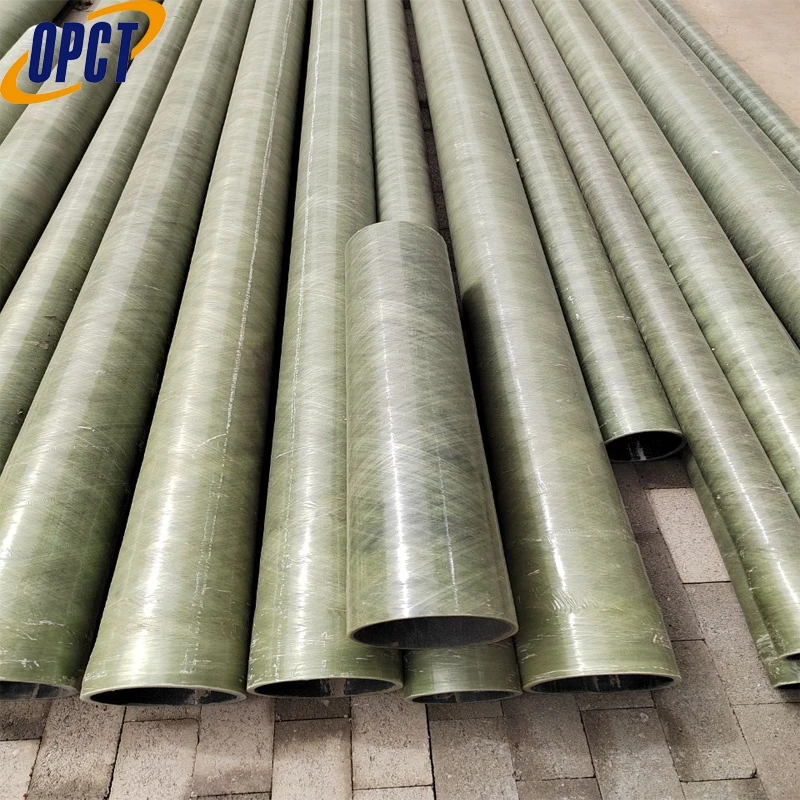

fibreglass angle

Health and safety are paramount in modern construction and manufacturing. Fibreglass angles contribute to safer working conditions; they are non-conductive, reducing electrical hazards when used in proximity to electrical components. Furthermore, their non-toxic nature ensures that they don't pose health risks, a consideration that is increasingly coming to the fore in an era focused on sustainable and responsible building practices.

Adopting fibreglass angles can significantly contribute to a green building strategy. Their longevity reduces the frequency and resources associated with replacement or repair, while their manufacturing process generally consumes less energy than metals. As the construction industry continues to push towards sustainability, these materials represent a pivotal shift that's both environmentally responsible and economically advantageous.

With durability, customization, and sustainability at the forefront, fibreglass angles are increasingly recommended by experts who recognize their advantages over traditional materials. Their application in critical sectors like telecommunications, transportation, and industrial infrastructures demonstrates a growing trust and reliance on their performance capabilities. As real-world experiences continue to validate these benefits, the authoritative consensus is clear fibreglass angles represent the future of structural components in demanding applications.

In conclusion, the adoption of fibreglass angles in various industries underscores their unmatched blend of properties suitable for innovative and future-focused construction practices. They offer an unparalleled solution that addresses modern demands for materials that are not only versatile and strong but also sustainable and safe, making them a smart choice for any forward-thinking enterprise.