Fiber reinforced plastic (FRP) pipes have emerged as a game-changer in the realm of modern engineering and construction, thanks to their robust performance characteristics and diverse applications. As an engineered material designed to outperform traditional piping systems, FRP pipes boast an impressive tensile strength-to-weight ratio, corrosion resistance, and versatility that are unparalleled in conventional metal or plastic alternatives.

Engineered with a matrix of fibers—typically glass or carbon—embedded in a plastic resin, FRP pipes provide enhanced mechanical properties. This hybrid construction offers structural integrity that withstands varying environmental conditions, including extreme weather and chemical exposure, making it highly suitable for industrial, municipal, and marine sectors. It is not uncommon to find FRP pipes utilized in chemical plants, desalination projects, and even wastewater management due to their ability to resist corrosive substances sustainably over time.

The process of selecting FRP pipes for a specific project demands a keen understanding of the parameters impacting their performance. Expertise in the composition of fiber materials, the type of resin used,

and reinforcement methods is critical. Manufacturers often use polyester, vinyl ester, or epoxy resin systems, depending on the application-specific requirements. Tailoring these elements correctly results in a pipe variant that can function optimally under specific temperature, pressure, and fluid dynamic conditions.

Among the standout advantages of using FRP pipes is their long lifecycle, which considerably reduces maintenance costs and downtime. This is primarily due to their non-corrosive nature, a factor that proves advantageous in installations exposed to saltwater, acidic flow streams, or aggressive industrial chemicals. The material properties also bolster hydraulic efficiency, as their smooth internal surfaces minimize friction losses, ensuring optimal flow rates with reduced pumping energy requirements.

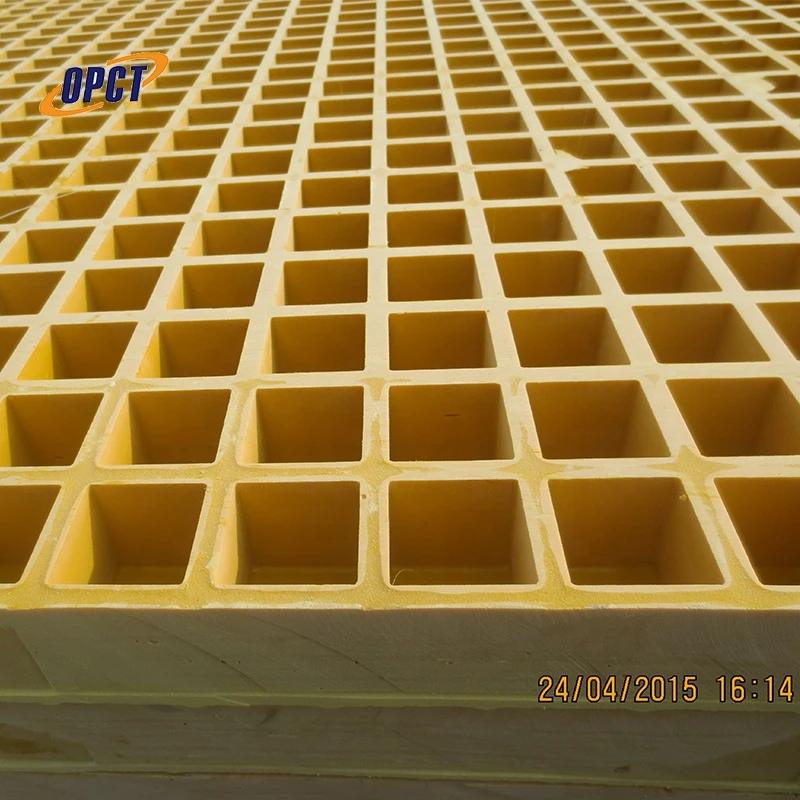

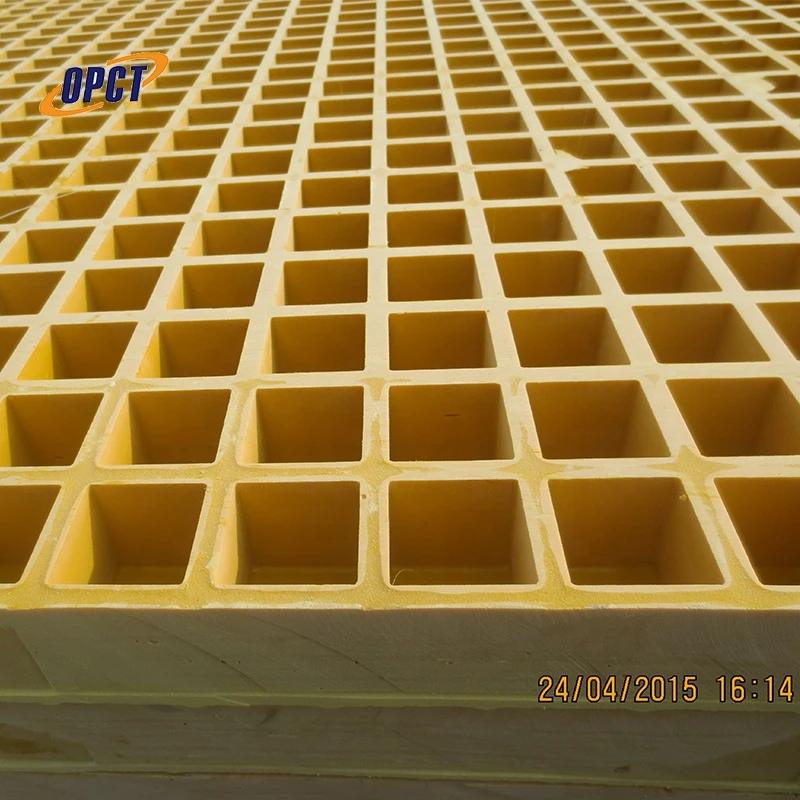

fiber reinforced plastic pipe

Another enriching aspect of FRP pipes is their lightweight design, which simplifies the logistics during transportation and installation compared to traditional pipes. This translates to reduced labor and machinery costs, especially in remote or difficult-to-access areas. Moreover, the technological advancements in joining methods, such as butt-and-wrap, adhesive bonding, or mechanical joints, have significantly streamlined installation processes, enhancing the reliability of pipe connections in high-stress environments.

Credibility in the FRP pipe market hinges on keeping abreast with testing standards and certifications such as ASTM standards, ISO compliance, and industry-specific certifications. These standards ensure that the products not only meet but exceed performance expectations under rigorous operational conditions. Purchasing from reputable manufacturers who adhere to these standards provides an added layer of trust and assurance of quality.

When choosing FRP pipes, engaging with suppliers who offer extensive guidance and support throughout the product lifecycle—from selection through installation and into operation—can greatly enhance the project outcomes. Many suppliers offer consultative services to help specify the correct product according to the detailed requirements of the project, supported by a wealth of case studies and application data.

In the evolving landscape of construction materials, FRP pipes epitomize a fusion of science and practicality. By integrating cutting-edge engineering with ecological sensibility and cost-efficiency, they stand as a testimony to the advancement of infrastructure technology. As global industries lean increasingly towards sustainable and durable solutions, FRP pipes remain at the forefront of transforming pipe infrastructure worldwide.