The Versatility and Applications of Fiberglass Tubes

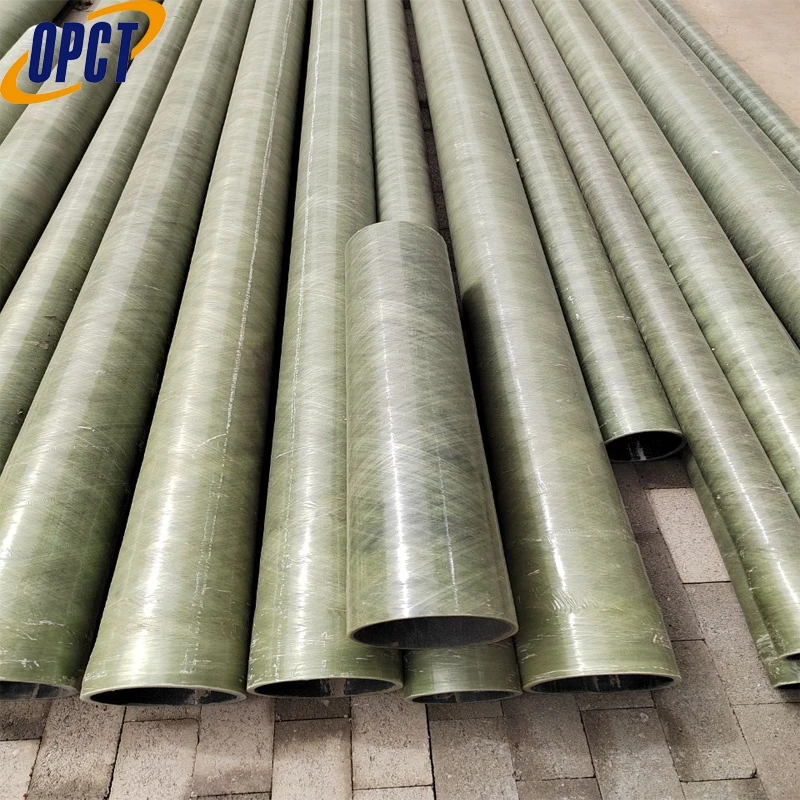

Fiberglass tubes have become increasingly popular in various industries due to their remarkable properties and versatility. Composed of a polymer matrix reinforced with glass fibers, these tubes combine strength, durability, and lightweight characteristics. As a result, they have found applications in construction, automotive, aerospace, and even sporting goods.

One of the primary benefits of fiberglass tubes is their exceptional strength-to-weight ratio. When compared to traditional materials such as steel or aluminum, fiberglass offers a lightweight alternative without compromising structural integrity. This characteristic is particularly advantageous in industries such as aerospace and automotive, where reducing weight can lead to increased fuel efficiency and improved performance. For example, in aircraft manufacturing, using fiberglass tubes can significantly lower the overall weight of the aircraft while maintaining the necessary strength for safety and stability.

Moreover, fiberglass tubes exhibit excellent resistance to corrosion and chemicals. Unlike metallic materials that can rust and degrade over time, fiberglass is impervious to a wide range of environmental conditions. This makes them ideal for use in harsh environments such as chemical processing plants, waste management facilities, and marine applications. In these settings, fiberglass tubes can withstand exposure to aggressive substances and harsh weather conditions, thereby enhancing their longevity and reducing maintenance costs.

In addition to their strength and corrosion resistance, fiberglass tubes are also non-conductive. This property makes them suitable for electrical applications, allowing for the safe transportation of electrical wiring without the risk of short circuits or electrical interference. Industries such as telecommunications frequently utilize fiberglass tubing to encase fiber optic cables, ensuring optimal performance and protection against external elements.

The manufacturing process of fiberglass tubes further contributes to their unique properties. Using techniques such as filament winding, pultrusion, or resin transfer molding, manufacturers can create tubes that meet specific dimensional and performance requirements. These processes allow for the production of custom shapes and sizes, catering to the diverse needs of various applications. Whether it's for support structures in construction or protective casings for electronic devices, fiberglass tubes can be tailored to fit the exact specifications required.

Additionally, the aesthetic appeal of fiberglass tubes cannot be overlooked. Available in a wide range of colors and finishes, they can enhance the visual aspect of products and structures. This is particularly relevant in design-conscious industries such as furniture and interior decor, where the appearance of materials plays a crucial role in consumer choices. Fiberglass tubes can be seamlessly integrated into modern designs while offering functional benefits.

The sustainability aspect of fiberglass is also an essential consideration. While traditional materials can involve significant environmental impact due to mining and processing, fiberglass is often viewed as a more sustainable option. Many manufacturers are exploring the use of recycled glass fibers and eco-friendly resins, contributing to a reduced carbon footprint and promoting green building practices.

In conclusion, the advantages of fiberglass tubes extend far beyond their initial appearance. Their strength, lightweight nature, corrosion resistance, and versatility make them an invaluable resource across multiple industries. As advancements in technology continue to improve manufacturing processes and material development, the applications for fiberglass tubes are likely to expand even further. From enhancing the performance of vehicles and aircraft to serving essential roles in construction and electronics, fiberglass tubes prove to be a smart choice for engineers and designers looking for durability and innovation. As we move towards a more sustainable future, the role of fiberglass in technological advancement will undoubtedly continue to grow, making it a material worth noting in the ongoing pursuit of efficiency and efficacy.