Fiberglass rods have emerged as a vital material across various industries, thanks to their versatility and robust performance attributes. For anyone considering fiberglass rod stock for their next project, understanding its applications, benefits, and handling can lead to a more informed decision. This article delves into a comprehensive exploration of fiberglass rod stock, with insights from industry experts who have championed its use across fields such as automotive, marine, and construction.

Fiberglass rod stock is renowned for its exceptional strength-to-weight ratio, which translates into a material that is not only lightweight but also significantly stronger than many metals per unit of weight. This property alone makes it an attractive alternative for replacing heavier materials in applications where weight reduction is critical. For instance, in the marine industry, fiberglass rods are extensively used to construct masts and supports due to their resistance to corrosion and excellent durability under harsh conditions. Experts in this field highlight that fiberglass rod stock can withstand prolonged exposure to saltwater, UV rays, and extreme temperatures, making it a reliable choice for building long-lasting structures.

In the automotive sector, fiberglass rods are often used for manufacturing components like bumpers and body panels. Industry professionals point out that the flexibility of fiberglass rod stock allows manufacturers to design complex shapes that are both functional and aesthetically pleasing. This flexibility, combined with the material’s impact resistance, provides an innovative solution for modern automotive design challenges. Moreover, the reuse and recyclability of fiberglass enhance its appeal as industries move towards more sustainable practices.

Construction experts are increasingly turning to fiberglass rod stock for rebar and reinforcing components. Unlike traditional steel rebar, fiberglass does not rust, offering a significant advantage in terms of the lifespan and maintenance costs of reinforced concrete structures. Civil engineers assert that using fiberglass rods in construction projects, especially those subjected to de-icing salts and high-moisture environments, can lead to lower lifetime costs and improved structural integrity.

When working with fiberglass rod stock, proper handling is essential to achieving optimal results. Manufacturers recommend storing fiberglass rods in a dry environment to prevent any potential damage before use. During the fabrication process, using appropriate safety measures such as protective eyewear, gloves, and respiratory masks is crucial to protect against airborne particles and glass fiber splinters. Cutting and shaping fiberglass rod stock should employ tools specifically designed for composites to ensure clean edges and precise dimensions.

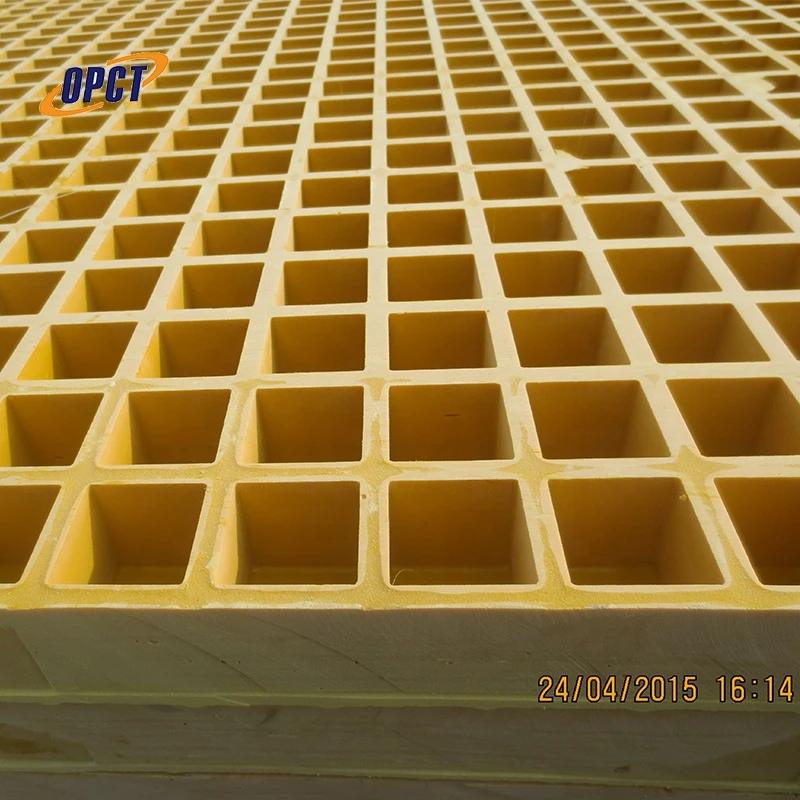

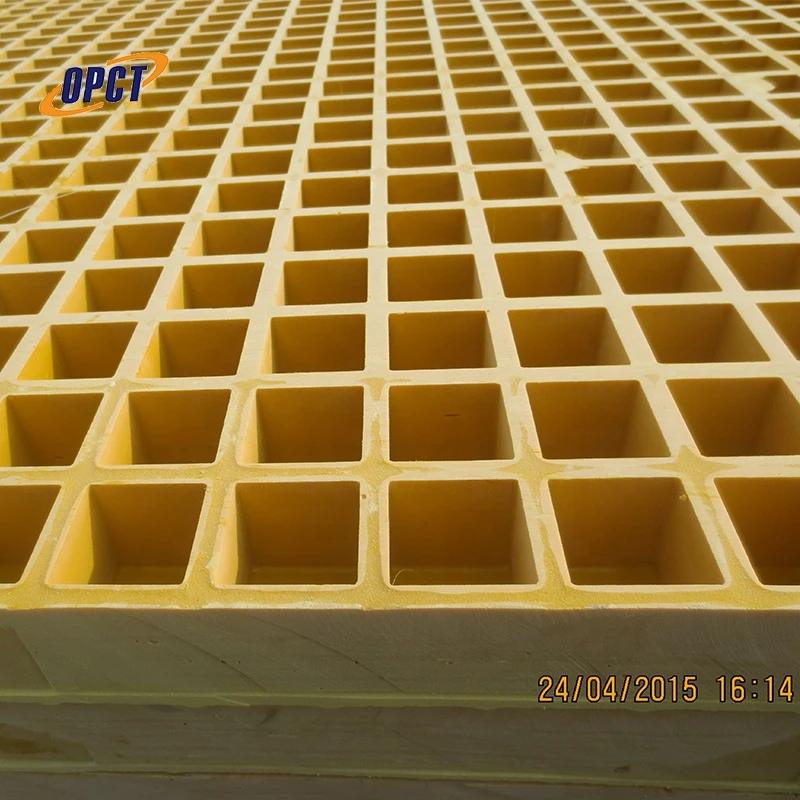

fiberglass rod stock

Technical expertise is required to effectively integrate fiberglass rod stock into existing systems. Designers and engineers must consider the material’s unique mechanical properties, such as its coefficient of thermal expansion and load-bearing capacities, to ensure compatibility with other components. Collaborating with materials specialists can provide valuable insights into achieving performance objectives while maximizing cost efficiency.

In educational initiatives, industry leaders promote curriculum development that emphasizes the benefits and uses of fiberglass materials. By equipping the next generation of engineers and designers with knowledge about innovative materials like fiberglass rod stock, the industry ensures ongoing advancement and adaptation to modern challenges.

While fiberglass rod stock presents numerous advantages, it is not without its limitations. For example, despite its resilience,

fiberglass can be susceptible to surface wear over time. Applying protective coatings can mitigate these effects and prolong the usability of the material in demanding environments.

Overall, the strategic use of fiberglass rod stock can significantly enhance the performance and longevity of products across various applications. Its unique blend of properties makes it an indispensable material in sectors striving for innovation and efficiency. By leveraging the strengths of fiberglass rod stock and adhering to expert guidelines for its application and handling, businesses can achieve greater product excellence and environmental stewardship.

Thus, fiberglass rod stock continues to assert its dominance as a cornerstone material in modern manufacturing and construction, supported by its unmatched durability, adaptability, and sustainable credentials.