Cooling towers, essential in many industrial processes, play a pivotal role in regulating temperatures and maintaining efficiency. Whether you're running a manufacturing plant, power station, or HVAC system, understanding the dynamics and benefits of modern cooling tower technology is paramount.

Cooling towers function by dissipating excess heat from industrial processes into the atmosphere, a necessary step for maintaining operational stability. The selection of a cooling tower hinges on factors such as size, material, and environmental impact, making it imperative for decision-makers to possess comprehensive knowledge about their options.

The expertise surrounding cooling tower designs is vast, with variations such as wet, dry, hybrid, and natural draft models, each serving distinct purposes. Wet cooling towers, for instance, are known for their efficient heat exchange process, utilizing water's high thermal capacity to cool air. Conversely, dry cooling towers are favored in regions facing water scarcity, replacing water with air-cooled heat exchangers.

One of the cutting-edge advancements in cooling tower technology is the integration of environmentally sustainable practices. Modern cooling towers incorporate features that minimize water usage and enable recycling, significantly reducing their ecological footprint. This aligns with the global shift towards sustainable industrial practices, as regulatory pressures and environmental concerns continue to mount.

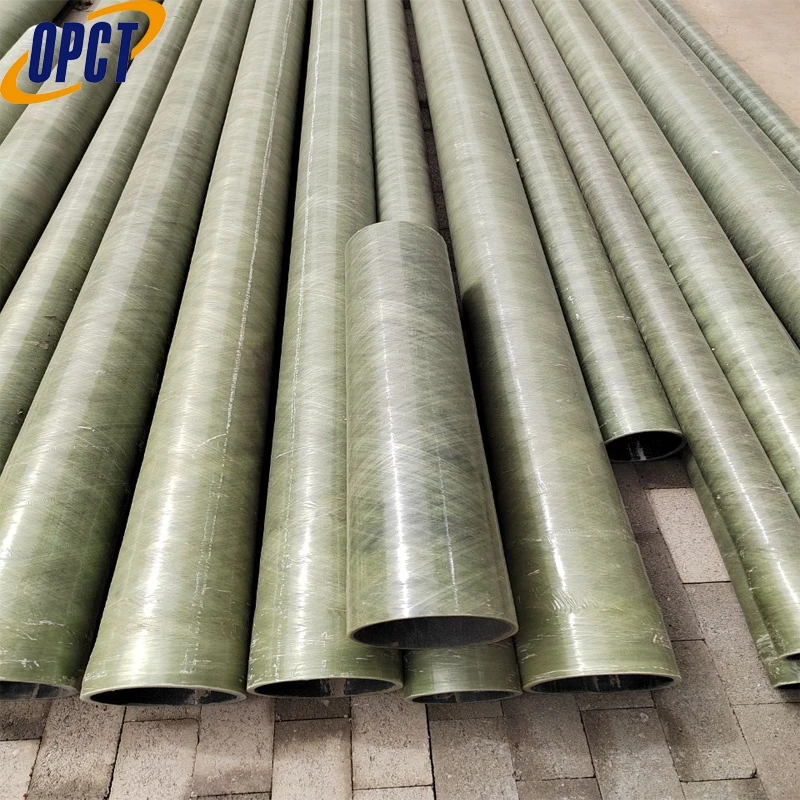

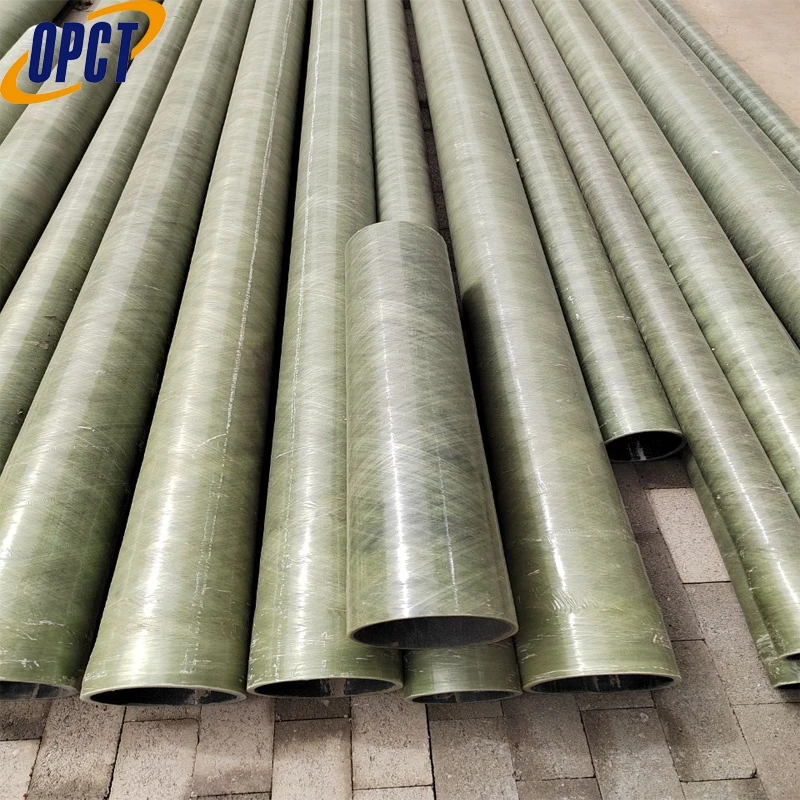

Delving into the mechanics of cooling towers unveils a complex interplay of thermodynamics and material science. The engineering behind these structures necessitates a deep understanding of fluid dynamics and thermal exchange, disciplines where expertise is non-negotiable. Professionals in the field continuously explore innovative materials like corrosion-resistant alloys, which prolong tower lifespan and improve efficiency.

cooling tower

Authoritativeness in the cooling tower domain also comes from an organization's proven track record and the reliability of its products. Leading manufacturers often engage in meticulous research and development, backed by certifications that establish their credibility. Utilizing cooling towers from reputable sources can significantly enhance operational trust and reduce downtime linked to equipment failure.

Trustworthiness also extends to the installation and maintenance processes of cooling towers. Expert practitioners recommend regular inspections and adherence to maintenance schedules to prevent inefficiencies and potential failures. Employing predictive maintenance techniques, such as thermal imaging and vibration analysis, allows for proactive measures, ensuring cooling systems remain at peak performance.

Case studies of successful cooling tower upgrades and installations further illustrate the benefits of expertise and innovation in this field. For example, a chemical manufacturing plant that transitioned to a hybrid cooling tower system not only witnessed a marked reduction in water consumption but also in operational costs, underscoring the importance of informed decision-making based on real-world experiences.

As industrial sectors push towards enhanced efficiency and sustainability, professionals involved in cooling tower operations must remain abreast of technological advances and regulatory changes. Conferences, industry publications, and professional networks provide valuable insights and foster knowledge sharing, crucial for maintaining a competitive edge.

In conclusion, cooling towers are the unsung heroes in maintaining industrial equilibrium, balancing the demands of efficiency, sustainability, and resilience. A commitment to fostering expertise, building authoritative reputations, and ensuring trustworthiness in cooling tower technologies can set the standard for future industrial success. As you navigate the complexities of cooling tower selection and maintenance, grounding your decisions in experience and expertise will yield benefits that are both economically and environmentally rewarding.