Understanding Chemical Tanks Types, Applications, and Safety Measures

Chemical tanks play a vital role in various industries, including pharmaceuticals, petrochemicals, food and beverage, and waste management. These tanks are specifically designed for the storage, processing, and transportation of hazardous and non-hazardous chemicals. Understanding the types, applications, and safety measures associated with chemical tanks is essential for ensuring compliance and protecting both human health and the environment.

Types of Chemical Tanks

Chemical tanks come in various shapes and sizes, tailored to the specific requirements of the substances they hold. The primary types of chemical tanks include

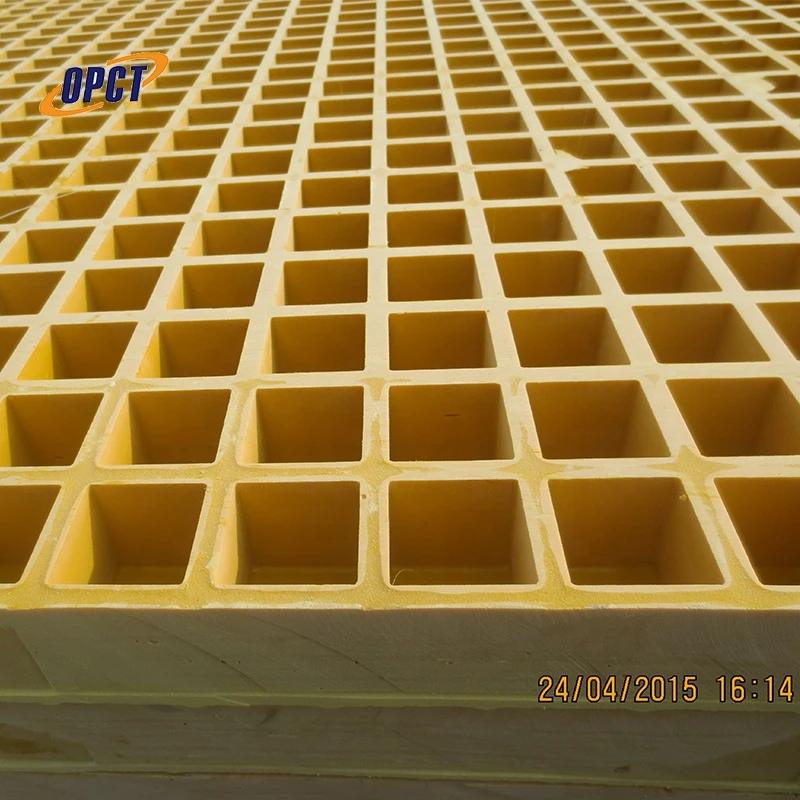

1. Above-Ground Storage Tanks (ASTs) These are commonly utilized for storing larger volumes of chemicals. Made from materials like steel or fiberglass, ASTs can be designed to accommodate varying chemical properties. They are often used in the petrochemical and bulk storage sectors.

2. Underground Storage Tanks (USTs) Commonly used for fuel and other hazardous substances, USTs are installed below ground level to minimize visual impact and reduce the risk of spills. Their construction is typically reinforced to withstand environmental pressures.

3. Pressure Vessels These tanks are designed to hold gases or liquids at a pressure substantially different from the ambient pressure. They are essential in industries like natural gas processing and chemical manufacturing, where reactions often occur under pressure.

4. Portable Chemical Tanks These tanks are designed for temporary storage and transportation of chemicals. They are often made from lightweight materials for ease of movement and are used in various applications, including construction and agriculture.

Applications of Chemical Tanks

The versatility of chemical tanks allows their use in diverse applications. In the pharmaceutical industry, they provide secure storage for raw materials and intermediates essential for drug production. In the food and beverage sector, food-grade chemical tanks ensure that ingredients are stored hygienically.

Furthermore, in the petrochemical industry, chemical tanks store raw materials like crude oil and refined products, which are crucial for fuel production. The wastewater treatment industry also utilizes chemical tanks for the storage of chemicals used in processing and treating waste, ensuring safe and effective disposal.

Safety Measures for Chemical Tanks

Given the potential hazards associated with the storage of chemicals, implementing robust safety measures is critical. These include

1. Material Selection The materials used to construct chemical tanks must be compatible with the substances stored within them. Factors such as temperature, pressure, and chemical reactivity should dictate the choice of materials to prevent leaks and failures.

2. Regular Inspections Scheduled maintenance and inspections are vital to identify wear and tear, corrosion, or potential leaks. Tank integrity is paramount, requiring inspections to be conducted by qualified professionals.

3. Secondary Containment This involves creating a backup system to contain leaks or spills if they occur. Often implemented in the form of a containment basin or dike, secondary containment minimizes environmental impact.

4. Training and Safety Protocols Employees handling chemicals must undergo regular training on safety procedures and emergency response. This training helps ensure that staff members can safely manage potential emergencies, such as spills or chemical reactions.

5. Hazardous Material Management Plans Developing comprehensive management plans that follow local, national, and international regulations is crucial. These plans should include guidelines on the safe storage, transportation, and disposal of hazardous materials.

Conclusion

Chemical tanks are indispensable in managing and storing various chemicals safely. With their diverse applications and the importance of safety measures, industries must prioritize proper tank selection, maintenance, and employee training to minimize risks and ensure compliance. By critically understanding the types and functions of chemical tanks, organizations can work towards a safer and more efficient operational environment.