Cable trays are an essential component in modern electrical infrastructure, providing a secure pathway to house and support power cables and communication wiring. Their significance spans across industries—from commercial buildings to industrial plants—ensuring an organized, efficient, and cost-effective cable management system.

When selecting a cable tray, understanding the specific needs of your project is paramount. As someone with extensive experience in electrical systems design, I cannot stress enough the importance of assessing load requirements, environmental conditions, and regulatory standards before making a decision. The right choice can enhance both safety and functionality, while a wrong one might lead to unnecessary complications and expenses.

One key consideration is the type of material used in cable trays. Aluminum trays, for example, are an excellent choice for locations where corrosion resistance is critical. Their lightweight nature also reduces installation labor, which can be a significant advantage in large-scale projects. Steel, on the other hand, offers superior strength and rigidity, making it ideal for environments requiring robust support for heavy cables.

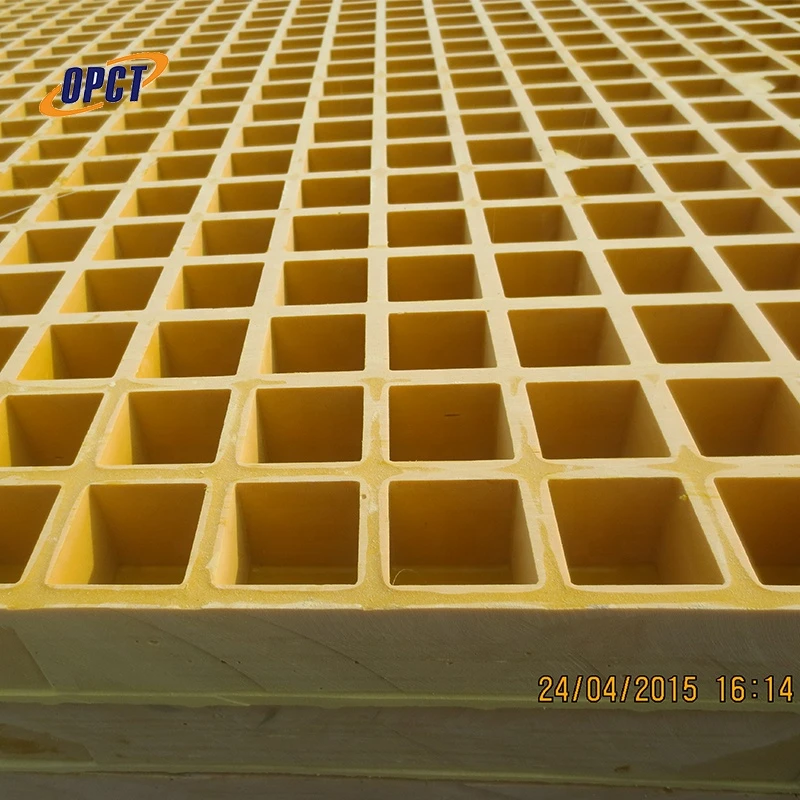

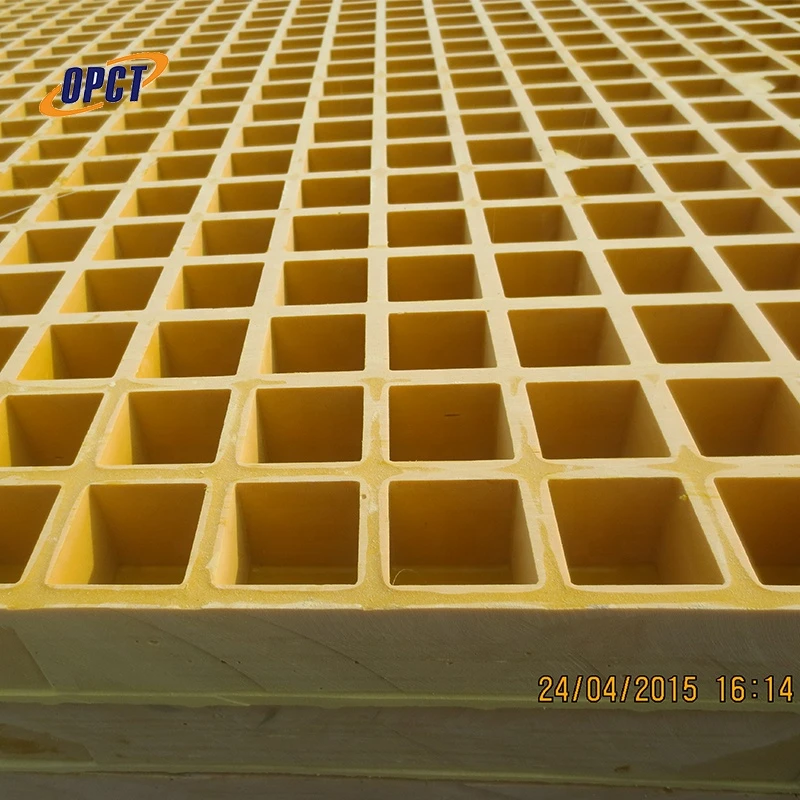

In environments with corrosive elements, such as oil refineries or chemical processing plants, stainless steel or fiberglass trays might be more suitable. These materials offer enhanced durability, ensuring a longer lifespan and reduced maintenance costs. From my professional experience, investing in a higher-quality material upfront often leads to substantial savings and fewer headaches in the long run.

Proper installation and compliance with standards, such as those set by the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC), are crucial to ensuring safety and effectiveness. These standards dictate requirements including load capacity, spacing, and support configurations. Failing to adhere to these guidelines can compromise both the integrity of the cable systems and the safety of personnel.

cable tray

It's also worth mentioning the integration of modern cable trays with smart technology. As industries move toward automation, cable trays are adapting. Integrated cable management systems now offer monitoring and data collection capabilities, providing real-time insights into system performance and potential issues. This advancement not only augments operational efficiency but also reinforces safety protocols, aligning with Industry 4.

0 initiatives.

The reliability of a cable management system can be significantly enhanced by using accessories such as dividers, covers, and barriers. Dividers help segregate power and data cables, minimizing electromagnetic interference and maintaining signal integrity. Covers and barriers, meanwhile, offer additional protection against physical damage and environmental factors.

A point often overlooked is the scalability of cable tray systems. As businesses grow, so too does their need for additional electrical capacity. Selecting a flexible cable tray system at the outset can accommodate future expansions, reducing the need for costly overhauls and ensuring continued compliance with evolving safety standards.

Finally, establishing partnerships with reputable manufacturers and suppliers can greatly enhance the trustworthiness and reliability of cable tray systems. Companies with a track record of quality and innovation provide valuable support, from initial selection to post-installation service.

The importance of cable trays in modern infrastructure cannot be overstated. With the right expertise and attention to detail, they not only provide a robust framework for electrical systems but also contribute significantly to the overarching goals of efficiency, safety, and sustainability. Understanding these dynamics solidifies your role as a knowledgeable and authoritative figure in electrical system planning and implementation, ultimately leading to successful project execution and operational excellence.