When it comes to versatile building materials, the 6 fiberglass tube stands out as a reliable choice for various industries. This tube, renowned for its unique blend of strength, durability, and lightweight properties, is an integral component in sectors ranging from construction to aerospace. Drawing on years of industry expertise and user experiences, let’s delve into the key aspects that make the 6 fiberglass tube an unparalleled option for professionals seeking high-performance materials.

First, let's discuss the inherent characteristics of fiberglass that contribute to its widespread application. Fiberglass, a form of reinforced plastic made from glass fiber embedded with resin, provides an exceptional strength-to-weight ratio. This quality is crucial for industries that demand structural integrity without the burden of excessive weight. The 6 fiberglass tube embodies these beneficial properties, making it a preferred choice for design engineers and constructors alike.

Durability is a defining feature of the 6 fiberglass tube. Resistant to a wide range of environmental factors, including moisture, UV radiation, and chemical exposure, this tube offers longevity in challenging conditions. Its non-corrosive nature ensures that it maintains structural integrity and aesthetic appeal over time, reducing maintenance costs and prolonging the lifespan of projects in which it is used. This level of resilience is crucial in industries such as marine engineering and outdoor construction, where materials are frequently exposed to harsh environments.

Moreover, the 6 fiberglass tube excels in thermal and electrical insulation. This makes it an excellent material for industries that require insulation properties, such as electrical and thermal utility installations. It is particularly advantageous in electrical applications due to its ability to resist electric currents, ensuring safety and reliability in power distribution and control systems. In thermal applications, it effectively minimizes heat transfer, which can improve energy efficiency and safety in industrial processes.

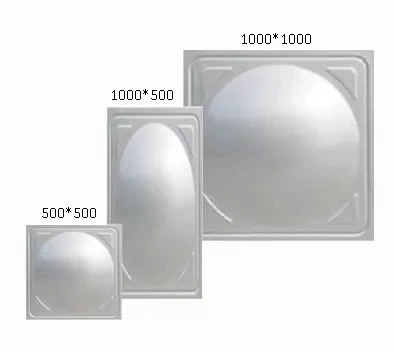

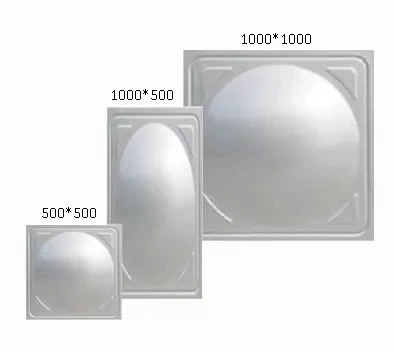

6 fiberglass tube

From a manufacturing perspective,

fiberglass is celebrated for its ease of fabrication. The 6 fiberglass tube can be custom produced to meet specific project requirements, whether it involves altering the dimensions, wall thickness, or shape. This customization capability is crucial for industries such as aerospace and automotive manufacturing, where precise specifications are necessary to achieve optimal performance and compliance with safety standards. Additionally, the ease of machining facilitates faster production times, enhancing project turnarounds and productivity.

Reliability in performance is not the sole reason for selecting the 6 fiberglass tube; it also stands as an eco-friendly alternative to traditional materials like steel and aluminum. The process of manufacturing fiberglass emits fewer pollutants and requires less energy compared to these metals. Moreover, the lighter weight of fiberglass reduces transportation emissions and energy consumption. For organizations aiming to align with sustainable practices, incorporating fiberglass components can significantly contribute to reducing their overall environmental footprint.

As a trusted material applied across various disciplines, the 6 fiberglass tube has been substantiated by numerous industry certifications and compliance standards. This includes meeting stringent criteria for structural applications, signaling quality and trustworthiness to industry professionals and consumers. Whether implemented in construction frameworks or critical aerospace components, the validation of these standards assures stakeholders of the material’s performance and safety.

In conclusion, the multifaceted advantages of the 6 fiberglass tube render it an indispensable resource for contemporary engineering and construction endeavors. Its blend of strength, durability, insulation properties, ease of customization, and environmental benefits make it a worthy investment for any project requiring reliable and sustainable materials. As industries evolve, the adaptability and proven track record of fiberglass tubes will undoubtedly continue to support and drive innovative solutions across the globe.