In the realm of construction and industrial applications, the 5-inch fiberglass tube stands out as a remarkable component due to its impressive blend of durability, versatility, and lightweight properties. This innovative material has captured the attention of engineers and project managers seeking reliable solutions for both traditional and cutting-edge construction needs.

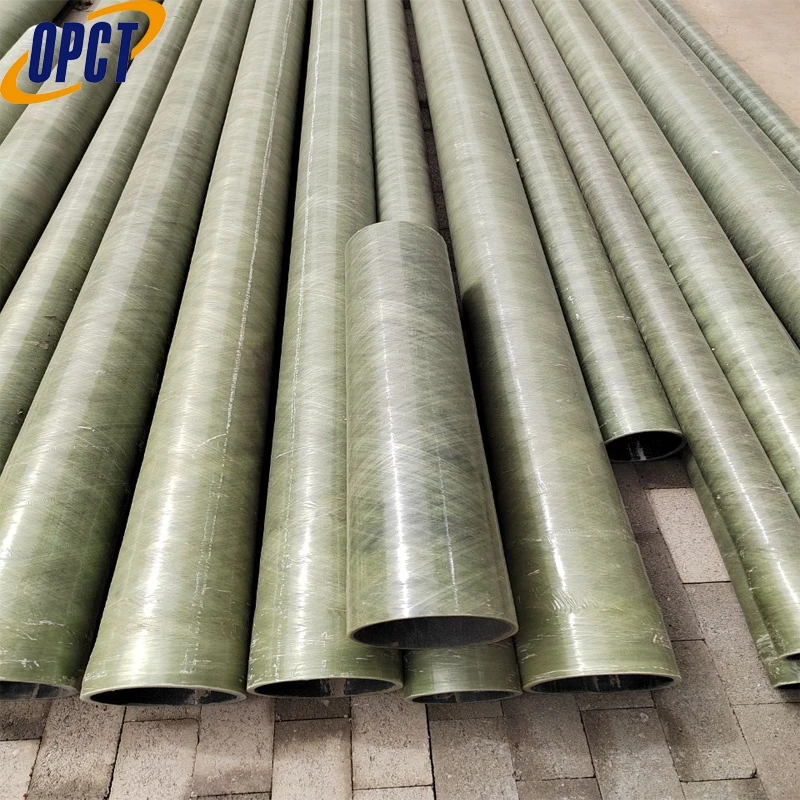

Fiberglass, a composite material made from fine fibers of glass, is revered for its strength-to-weight ratio, corrosion resistance, and dielectric properties. The 5-inch fiberglass tube, typically composed of high-density fiberglass weaves or mats, is increasingly being utilized across a range of industries, from aerospace to infrastructure. Its superior resilience against harsh environmental conditions, including moisture and ultraviolet radiation, makes it an ideal choice for outdoor applications.

One of the primary advantages of the 5-inch fiberglass tube is its lightweight nature, which significantly reduces the overall weight of structures without compromising strength. This advantage is particularly beneficial in the transportation and aerospace sectors, where reducing weight is crucial for efficiency and fuel economy. Moreover, the tube's non-conductive nature provides an extra layer of safety in electrical applications, reducing the risk of accidental shorts and ensuring stability in high-voltage environments.

The industrial sector also benefits from the use of fiberglass tubes. Their robustness is evident in their widespread use for building supports, handrails, conduits, and frameworks where steel or aluminum might otherwise corrode. The tube’s inherent corrosion resistance remains a key feature, particularly in chemical plants and water treatment facilities, where exposure to corrosive substances is frequent.

In terms of customization, the 5-inch fiberglass tube can be tailored to meet specific requirements. Various wall thicknesses and finishes are available, providing additional flexibility for engineers and designers. Fiberglass can also be modified with additives to enhance attributes such as flame retardance or specific tensile strengths, making it a bespoke solution for specialized projects.

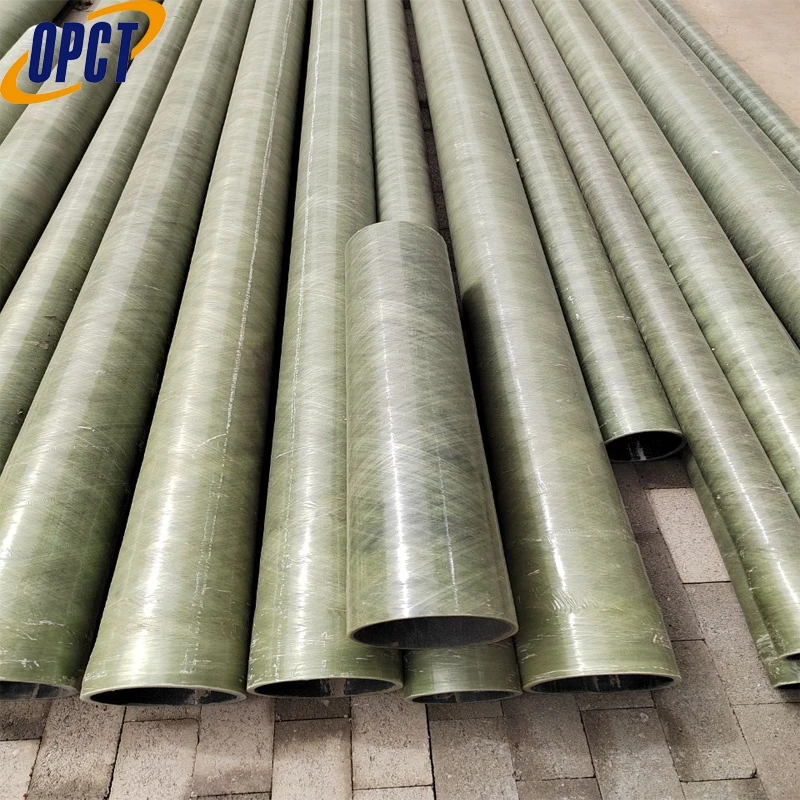

5 inch fiberglass tube

From a maintenance perspective, fiberglass requires minimal upkeep compared to metals or wood, translating into cost savings over time. The material's longevity ensures that replacements and repairs are infrequent, which is a significant advantage for budget-conscious projects with long life cycles.

Another compelling aspect is the ease of installation. Given its lighter weight, the logistics of transporting and erecting fiberglass tubes are simpler and more cost-effective. This simplicity reduces labor costs during installation and allows for faster project completion times, a crucial factor in industries like infrastructure development, where time can equate to significant monetary savings.

Environmental considerations continue to shape material selection, and fiberglass aligns well with sustainable practices. As a recyclable material, it contributes to reducing construction waste and promotes a circular economy in industrial applications.

Moreover, the fiberglass manufacturing process is continually evolving to enhance its environmental footprint, with many producers adopting greener practices and sustainable resins. These developments further position fiberglass tubes as a top choice for projects prioritizing environmental responsibility alongside performance.

In conclusion, the 5-inch fiberglass tube embodies a robust combination of strength, versatility, and sustainability, making it an indispensable asset across multiple industries. Its capacity to adapt through customization enhances its appeal, ensuring it meets varied and complex demands with unrivaled efficiency. As industries continue to evolve, fiberglass tubes offer a forward-thinking solution that aligns with modern requirements for high-performance, sustainable materials.