When it comes to stability and performance in lightweight construction materials, a product that often stands out is the 3mm fibreglass rod. This slender yet robust component serves as a backbone in numerous industries ranging from kites and model aircraft to structural support in fabric architecture. The intrinsic qualities of fibreglass make these rods not just functionally superior, but also economically viable for a variety of applications.

The use of 3mm fibreglass rods in kite construction is a testament to their strength-to-weight ratio. Enthusiasts and professionals alike choose these rods because they are lightweight yet sturdy, ensuring that kites can perform admirably in varying wind conditions. Unlike other materials that may fracture under stress or prolonged exposure to the elements, fibreglass rods maintain their integrity, offering resilience against impacts and weathering. Such reliability is crucial for kites that are expected to dance gracefully in the sky, soaring high without frequent maintenance or risk of breakage.

In the realm of model aviation, particularly remote-controlled aircraft, precision and durability are paramount. The 3mm fibreglass rod is frequently employed to construct lightweight fuselages, tail booms, and wing spars. Its structural integrity provides the necessary support while allowing for nimble maneuverability. Hobbyists and serious aviators benefit from the predictable performance characteristics of fibreglass, which withstands operational stresses that would otherwise compromise flight dynamics. These rods also lend themselves well to modifications, accommodating enthusiasts who wish to tweak their designs for optimal performance.

Moreover,

the architectural applications of these fibreglass rods are numerous and innovative. In tensile structures and fabric architecture, 3mm rods are utilized as support elements that require minimal maintenance despite constant exposure to environmental factors. Their non-corrosive nature means that they outperform many metal alternatives, which are prone to rust and require regular upkeep. This durability makes fibreglass rods an economically sound choice for architects and builders seeking both aesthetic appeal and long-term performance.

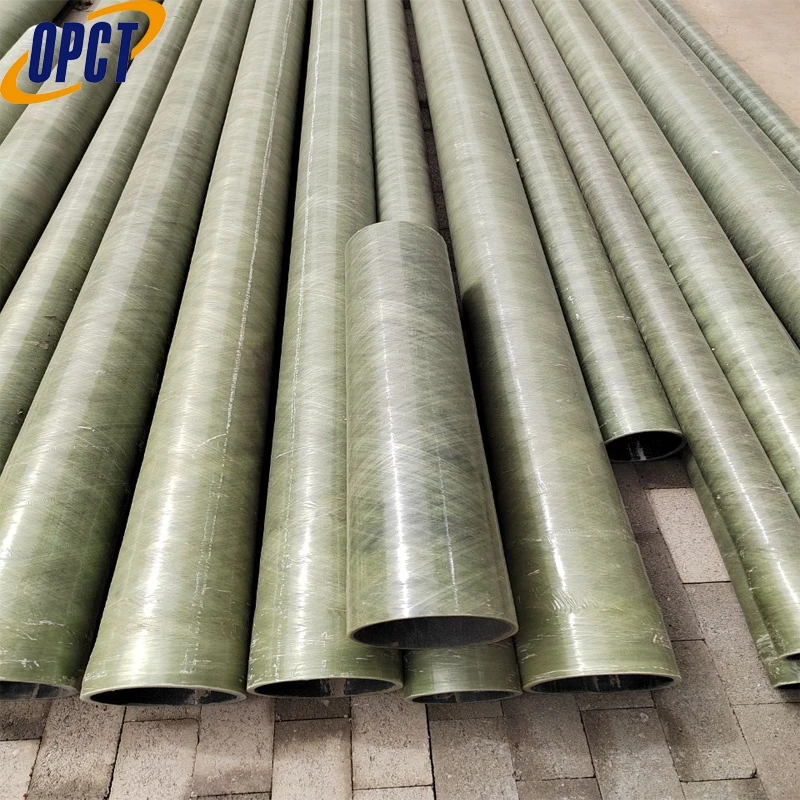

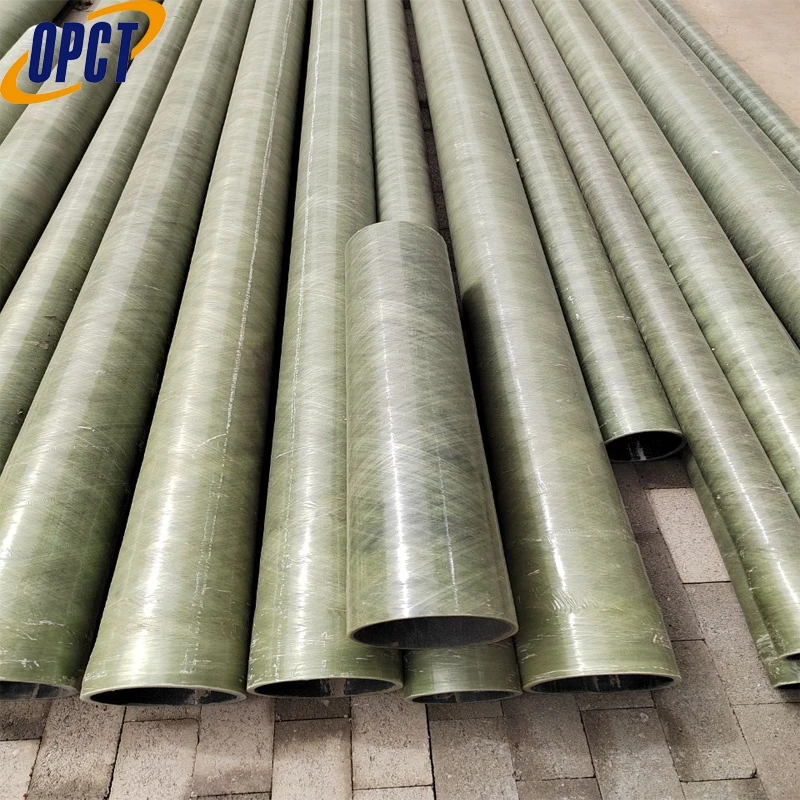

3mm fibreglass rod

From a technical standpoint, the manufacturing process of fibreglass rods contributes significantly to their reliability and versatility. The fibers are strategically aligned and bonded with resin to create a composite that exhibits both rigidity and flexibility. This combination of traits allows the rods to absorb stress and return to their original shape, which is critical in applications that demand cyclic or dynamic loading. Unlike traditional materials that may deform under similar conditions, fibreglass retains its structural form, ensuring that designs and constructions remain intact over time.

For industries that prioritize sustainability, the environmental impact of materials is an ever-present concern. Fibreglass rods offer an advantage here as well, being recyclable and less energy-intensive to produce than many metal counterparts. Companies striving to minimize their carbon footprint can benefit from incorporating fibreglass components into their designs, thus aligning with eco-friendly practices and reducing waste.

In summary, the 3mm fibreglass rod stands out as a versatile, durable, and environmentally responsible choice for a myriad of applications. Its combination of strength, lightweight properties, and resistance to environmental degradation makes it an invaluable asset across different fields, from recreational pursuits to industrial and architectural projects. Professionals and hobbyists alike recognize the added value these rods bring, as they contribute to enhanced performance, longevity, and sustainability. By choosing fibreglass, users invest not just in superior material but also in a future of innovation and ecological mindfulness, solidifying fibreglass rods as both a contemporary solution and a forward-thinking choice.