The 30-gallon chemical tank is a critical component in industries ranging from manufacturing to water treatment. These tanks serve as reliable storage solutions for a variety of chemicals, ensuring safe handling and compliance with industrial standards. Their design, capacity, and material composition make them indispensable.

One of the foremost considerations in selecting a chemical tank is understanding its construction and material. High-density polyethylene (HDPE) is a popular choice due to its robustness and resistance to a wide array of chemicals. This makes HDPE tanks suitable for storing corrosive substances as well as other hazardous materials. The molecular stability of HDPE ensures that it does not react with the chemicals stored, providing an added layer of safety.

A 30-gallon tank’s capacity is ideal for both small-scale industrial applications and as an auxiliary solution for larger systems. Its size allows for easy integration into existing processes without the logistical challenges that accompany larger tanks. Furthermore, the relatively small footprint of a 30-gallon tank enables more strategic placement within facilities, optimizing workflow and space utilization.

Innovative design features of modern 30-gallon chemical tanks often include seamless construction to prevent leaks, UV stabilization to withstand outdoor storage, and customizable fittings to enhance compatibility with existing equipment. Whether used in agriculture, pharmaceuticals, or chemical processing, these tanks can be tailored to specific requirements. This adaptability reflects their essential role across diverse operations.

For industries focused on compliance and safety, a 30-gallon chemical tank often meets or exceeds stringent industry standards such as those set by the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA). Ensuring tanks are certified not only supports safe operations but also bolsters company reputation as being committed to responsible chemical handling and storage.

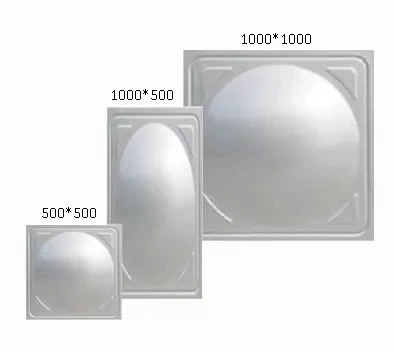

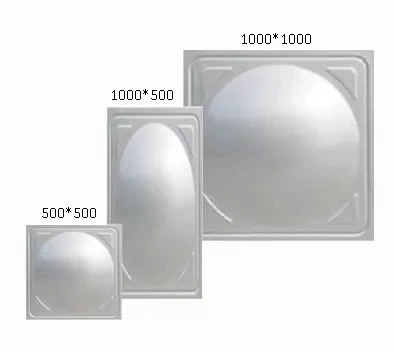

30 gallon chemical tank

However, the benefits of these tanks extend beyond mere compliance. In an era where sustainability is paramount, many manufacturers are emphasizing recyclable materials and energy-efficient production methods. This environmentally conscious approach aligns with the increasing demand for products that minimize ecological impact. By choosing a sustainably manufactured tank, businesses contribute to broader environmental goals while maintaining operational efficiency.

Maintenance and longevity are additional factors where the 30-gallon chemical tank excels. By opting for tanks with enhanced resistance to punctures and dents, made possible through advanced engineering techniques, companies can significantly reduce the downtime associated with repairs and replacements. Regular inspection and cleaning protocols further maximize the lifespan of the tanks, ensuring consistent performance over time.

When discussing the economic aspects, it’s pertinent to note the cost-effectiveness of a 30-gallon chemical tank. Its initial purchase price combined with the low maintenance costs represents an excellent return on investment. In scenarios where multiple tanks are required, the ability to easily transport and install 30-gallon units can economize labor and installation expenses.

Moreover, choosing the right tank supplier is crucial. A reputable manufacturer or distributor not only offers high-quality products but also provides critical pre-purchase advice and post-sale support, ensuring that clients receive a solution that matches their unique operational needs. Establishing a relationship with an experienced supplier enhances trust and reliability, facilitating seamless operations.

In summary, a 30-gallon chemical tank is more than just a storage solution; it is a cornerstone of safe, efficient, and sustainable industrial practices. Its adaptability, compliance with safety standards, and cost-effectiveness make it an unparalleled choice for businesses seeking to optimize their chemical storage strategies. Whether as a standalone unit or part of a larger storage system, its role in supporting industrial processes is invaluable and indisputable. By understanding and leveraging the unique benefits and features of these tanks, companies can enhance their operational capabilities while adhering to rigorous safety and environmental standards.