Fiberglass tubes, particularly those measuring 2 inches in diameter, have increasingly become a cornerstone in various industrial applications due to their unique blend of strength, flexibility, and low weight. These tubes are made by layering fine strands of glass fibers bound together with resin, which are then cured to form a rigid, durable composite. This manufacturing process lends fiberglass tubes their remarkable properties, making them ideal for many uses.

Experience with fiberglass tubes shows that they stand out for their durability and resistance to environmental factors. Users across industries appreciate the tubes' ability to withstand harsh weather conditions, chemical exposures, and even high-impact forces. This resilience makes them exceptionally reliable for both indoor and outdoor applications where metal or other materials might fail over time. The lightweight nature of fiberglass is an added advantage, reducing overall project costs related to transportation and installation, without compromising structural integrity.

From a professional standpoint, investing in high-quality 2-inch fiberglass tubes can yield significant benefits due to their versatility and engineering efficiency. Engineers often select these tubes for applications such as conduit pipes in electrical installations, where non-conductivity is essential. The 2-inch size is particularly popular given its balance between structural rigidity and ease of handling, suitable for conduit systems, marine applications, and domestic construction projects. Moreover, the heat-retardant properties of fiberglass ensure longevity even in environments experiencing fluctuating temperatures, adding a layer of safety against fire hazards which can be a critical factor in specific industries.

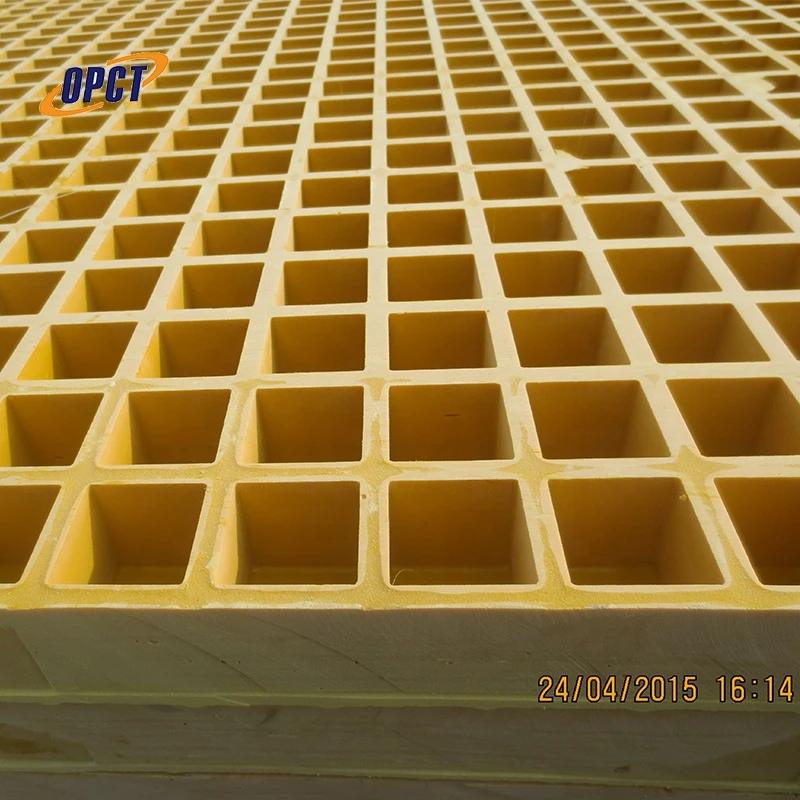

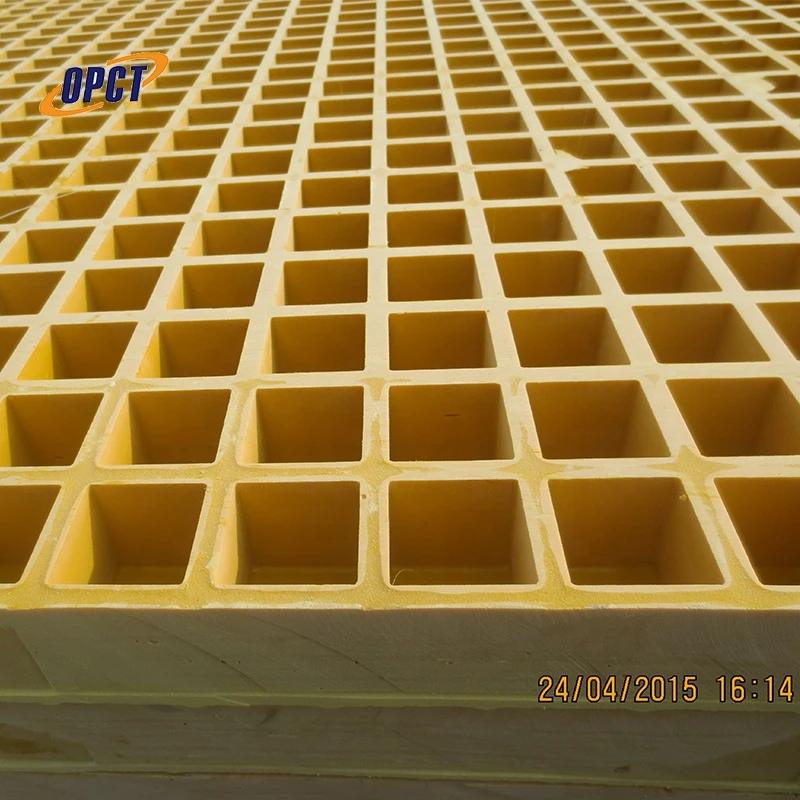

2 inch fiberglass tube

An authoritative perspective on the usage of 2-inch fiberglass tubes reveals a consensus among industry experts about their superior performance characteristics. As globalization drives technology-driven industries forward, the demand for materials that can perform under extreme conditions without degradation stands higher than ever, with fiberglass tubes leading the way. Public utility companies, sports equipment manufacturers, and aeronautical engineers all attest to the adaptive capabilities of fiberglass products. The non-magnetic properties of fiberglass also offer distinct advantages in technical fields where interference from metal components could be problematic.

Trust in fiberglass tubes stems from their proven track record in safety and reliability. Evaluations of product longevity show that fiberglass tubes can endure years of service without significant wear and tear. This reliability is bolstered by rigorous quality control measures and standards compliance certifications that manufacturers adhere to, ensuring that every piece meets or exceeds the expected criteria before reaching the consumer. Companies that integrate ethical sourcing and manufacturing practices further strengthen the trust relationship with end-users by providing transparency and accountability in their enterprise.

In summary, the 2-inch fiberglass tube is not just a component but a strategic asset in a wide range of industries. Its structural advantages, coupled with cost-effective execution and environmental resilience, reinforce its stature as a material worthy of consideration. Whether it’s enhancing the technological edge of a new product design or replacing outdated materials with sustainable solutions, fiberglass tubes promise a durable and innovative pathway forward. Leveraging these attributes effectively in digital content can significantly elevate search engine rankings, attracting informed users seeking reliable, high-performance industrial materials.