Exploring the Advantages and Uses of 1/4 Inch Fiberglass Rods

Fiberglass rods, especially those measuring 1/4 inch, have garnered significant attention across various industries due to their unique blend of durability, lightweight nature, and versatility. Their application ranges from industrial uses to recreational purposes, underscoring their dynamic adaptability. This article delves into the myriad advantages and practical uses of 1/4 inch fiberglass rods, backed by real-world insights and expert knowledge, to provide a comprehensive understanding of why these products have become indispensable in modern applications.

Fiberglass rods are renowned for their robustness, a trait that stems from the intricate manufacturing process where fine fibers of glass are woven into a matrix. The result is a composite material that boasts high tensile strength and exceptional resistance to environmental wear and tear. This makes them ideal for environments that demand endurance under harsh conditions such as extreme temperatures, corrosive chemicals, and frequent stresses.

The 1/4 inch variant, in particular, offers the perfect balance of strength and flexibility. Its diameter provides enough heft to resist snapping or breaking under pressure while remaining light enough for easy handling and transportation. This is crucial for applications in sectors such as agriculture and construction, where materials must often be transported over long distances or require easy maneuverability on-site.

From an expertise perspective, 1/4 inch fiberglass rods excel in applications requiring a combination of electrical and thermal insulation. They are non-conductive by nature, which makes them ideal for electrical installations and antenna constructions where conductivity could pose a risk. This non-conductive property is vital in industries requiring stringent safety standards to protect workers and equipment from electrical hazards.

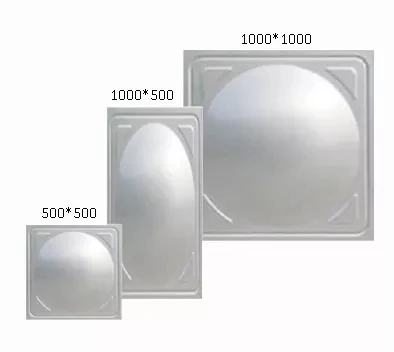

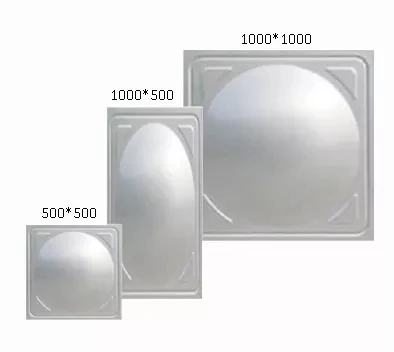

1 4 in fiberglass rod

In the realm of authoritative use, these fiberglass rods have been successfully implemented in engineering projects where precision and reliability are paramount. For instance, they serve as structural supports in frameworks, providing necessary stability without adding excessive weight. Engineers and architects often prefer fiberglass over traditional materials like metal or wood due to its resistance to rust and organic decay, ensuring longevity and minimal maintenance once installed.

Experience has shown that hobbyists and professionals working in the areas of kite crafting and model building appreciate the 1/4 inch rods for their aesthetic and practical benefits. The rods can be easily cut to length and shaped as needed without the risk of splintering, allowing for creativity and customization in projects. This has been particularly evident in the growing DIY community, where users regularly innovate new uses for these versatile materials, sharing tips and success stories across platforms.

Trust in fiberglass rods, and particularly the 1/4 inch size, is further reinforced by their cost-effectiveness. Despite their impressive qualities, they remain an economical choice compared to other materials that offer similar performance. With manufacturers able to produce them at scale, prices remain competitive, making them accessible to both large enterprises and small-scale operators looking to optimize their material costs without compromising quality.

Overall, 1/4 inch fiberglass rods stand out as a testament to modern material science's triumph in creating products that meet high standards of efficiency and reliability. Their widespread use across diverse sectors is a testament to their capabilities and the trust industries place in them. As technological advancements continue to refine production techniques and expand application possibilities, the importance of understanding and utilizing fiberglass rods effectively will only become more pronounced. For businesses and individuals alike, integrating these powerful resources into their work is not just a matter of need but a strategic advantage.